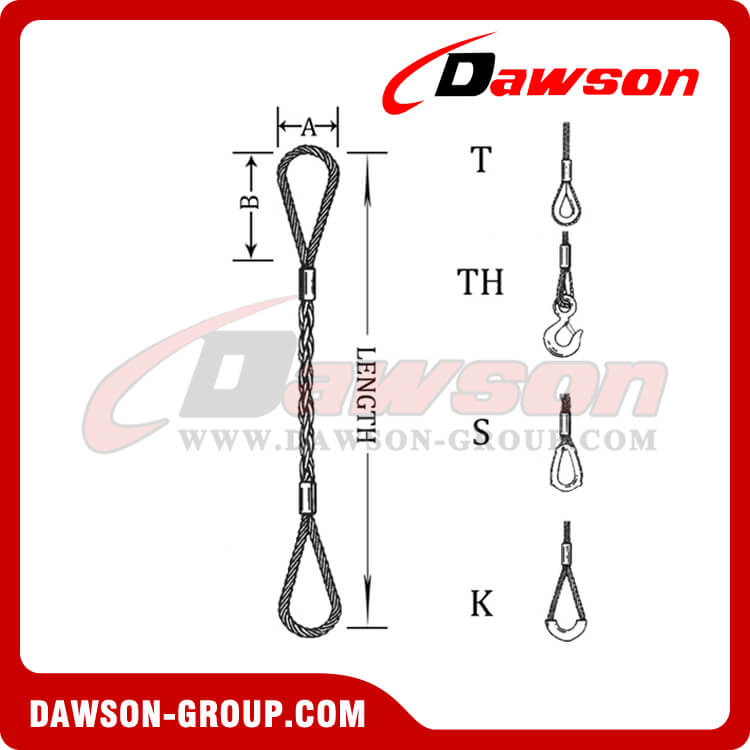

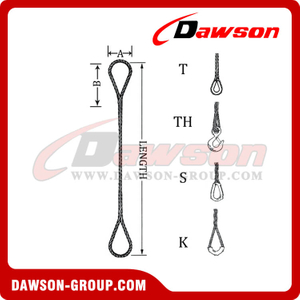

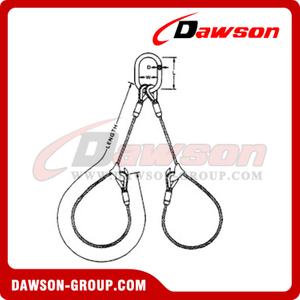

Single Part Body, Mechanical Splice

The eye or loop end preparation is formed using the Flemish Eye Splice. This splice is then secured by swaging a metal sleeve over the strang ends, at the junction of the splice. There are no exposed wires and serving is not required.

The swage metal sleeve flows around the wires and prevents the strands from unlaying. Depending on the application, the sleeve can be steel, aluminum, or stainless steel.

A single part, mechanical splice sling is economical, offers the highest rated capacity of any spliced sling, and loads ate applied along the center line of the sling.

Flemish Eye Splice:

The Flemish Eye is spliced by unlaying one half of the strands from the other half at the core. The two halves are joined at the bearing point of the eye and laid back in the opposite direction. The final step is to secure the strands with a metal sleeve.

WS71-E-E,T,TH,S&K

Rated Capacity –Tons(2000lbs.)EIP-IWRC |

| Rope Diameter inch | Vertical | Choker* | Basket Hitches | Eye Dimensions inch |

|  |  |  |  |  | A | B |

| 1/4 | 0.65 | 0.48 | 1.3 | 1.10 | 0.91 | 0.65 | 2.0 | 4 |

| 5/16 | 1.00 | 0.74 | 2.0 | 1.70 | 1.40 | 1.00 | 2.5 | 5 |

| 3/8 | 1.40 | 1.10 | 2.9 | 2.50 | 2.00 | 1.40 | 3.0 | 6 |

| 7/16 | 1.90 | 1.40 | 3.9 | 3.40 | 2.70 | 1.90 | 3.5 | 7 |

| 1/2 | 2.50 | 1.90 | 5.1 | 4.40 | 3.60 | 2.50 | 4.0 | 8 |

| 9/16 | 3.20 | 2.40 | 6.4 | 5.50 | 4.50 | 3.20 | 4.5 | 9 |

| 5/8 | 3.90 | 2.90 | 7.8 | 6.80 | 5.50 | 3.90 | 5.0 | 10 |

| 3/4 | 5.60 | 4.10 | 11.0 | 9.70 | 7.90 | 5.60 | 6.0 | 12 |

| 7/8 | 7.60 | 5.60 | 15.0 | 13.00 | 11.00 | 7.60 | 7.0 | 14 |

| 1 | 9.80 | 7.20 | 20.0 | 17.00 | 14.00 | 9.80 | 8.0 | 16 |

| 1 1/8 | 12.00 | 9.10 | 24.0 | 21.00 | 17.00 | 12.00 | 9.0 | 18 |

| 1 1/4 | 15.00 | 11.00 | 30.0 | 26.00 | 21.00 | 15.00 | 10.0 | 20 |

| 1 3/8 | 18.00 | 13.00 | 36.0 | 31.00 | 25.00 | 18.00 | 11.0 | 22 |

| 1 1/2 | 21.00 | 16.00 | 42.0 | 37.00 | 30.00 | 21.00 | 12.0 | 24 |

| 1 5/8 | 24.00 | 18.00 | 49.0 | 42.00 | 35.00 | 24.00 | 13.0 | 26 |

| 1 3/4 | 28.00 | 21.00 | 57.0 | 49.00 | 40.00 | 28.00 | 14.0 | 28 |

| 2 | 37.00 | 28.00 | 73.0 | 63.00 | 52.00 | 37.00 | 16.0 | 32 |

| 2 1/4 | 44.00 | 35.00 | 89.0 | 77.00 | 63.00 | 44.00 | 18.0 | 36 |

| 2 1/2 | 54.00 | 42.00 | 109.0 | 94.00 | 77.00 | 54.00 | 20.0 | 40 |

| 2 3/4 | 65.00 | 51.00 | 130.0 | 113.00 | 92.00 | 65.00 | 22.0 | 44 |

| 3 | 77.00 | 60.00 | 153.0 | 133.00 | 108.00 | 77.00 | 24.0 | 48 |

| 3 1/2 | 102.00 | 79.00 | 203.0 | 176.00 | 144.00 | 102.00 | 28.0 | 56 |

Rated capacities basket hitch based on D/d Ratio of 25.

Rated capacities based on pin diameter no larger than natural eye width or less than the nominal sling diameter.

Rated capacities based on design factor of 5. Horizontal sling angles less than 30° shall not be used. All capacities are based on new and unused slings.

* See Choker Hitch Rated Capacity Adjustment.

**Working Load Limit.

WARNING: Do not use, or allow the use of the products in this catalogue, unless the user has read and understands the applicable instructions and product warnings. Information available upon request.

Wire Rope Sling Application Hitches

1. Vertical- The Vertical, or straight, attachment is simply using a sling to connect a lifting hook or other device to a load. Full rated load of the sling may be used, but never exceeded. A tagline should be used on such a lift to prevent rotation, which can damage the sling. A wire rope sling with a hand-tucked splice can unlay and fail if the sling is allowed to rotate.

2. Choker- Choker Hitch configurations reduce the rated capacity of a sling by 20 to 25 percent. If a load is hanging free, the normal choke angle is approximately 135°. When the choke angle is less than 120°, an adjustment in the choker rated capacity must be made(see illustration below). Extreme care should be taken to determine the choke angel as accurately as possible. As indicated in the table below, the decrease in rated capacity is dramatic.

Choker Hitch

RATED CAPACITY ADJUSTIMENT

Choke IWRC and Fiber Core Rope

Angle Percent of

(Degrees) Choker Rated Capacity

Over 120 100

90-120 87

60-89 74

30-59 62

Up to 29 49

Angle Adjustment

Rated capacity adjustment for slings in choker hitch when angle is less than 120°. Choke angles greater than 135°are unstable and should not be used.

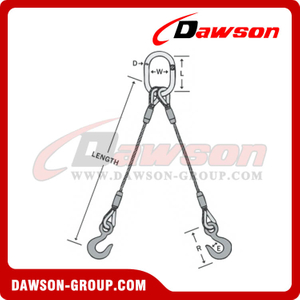

3. Basket- Basket hitched distribute a load equally between the two legs of a sling, within limitations imposed by the angles at which legs are rigged to the load(see discussion of sling angles).

Basket Hitch

CAPACITY ADJUSTMENT

Angle Percent of Single Leg

(Degrees) Capacity

90 200

60 170

45 140

30 100

Angle

A basket hitch has twice the capacity of a sling leg only if legs of sling are vertical, and only if D/d ratio is 25:1 and it is vertical. D/d>25:1 per ANSI B30.9.

WARNING: Do not use, or allow the use of the products in this catalogue, unless the user has read and understands the applicable instructions and product warnings. Information available upon request.

Reeving

Revving through connections to load increases load on connections fitting by as much as twice.

Do not reeve.

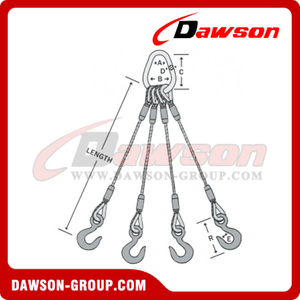

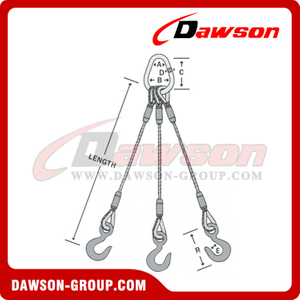

Triple and Quad Leg Slings

Triple leg slings have 50% more capacity than double leg only if the center of gravity is in center of connection points and the legs are adjusted properly(equal share of the load)

Quad leg slings offer improved stability but do not provide increased lifting capacity.

Center of Gravity(COG)

The location of the center of gravity to the pick points is an important consideration.

COG and Sling Loading

When lifting vertically, the load will be shared equally if the center of gravity is spaced equally between the pick points, as in the first illustration at right. If the weight of the load is 10,000 lbs., then each sling will have a load of 5,000 lbs. and each shackle and eyebolt will also have a load of 5,000 lbs.

When the center of gravity is not equally spaced between the pick points, as in the second illustration, the slings and fittings will not carry an equal share of the load. The sling connected to the pick point closest to the center of gravity will carry the greatest share of the load. Sling 2 is closest to COG. It will have the greatest share of load.

Sling 2 = 10,000 × 8 /(8+2)= 8,000

Sling 1 = 10,000 × 2 /(8+2)= 2,000

WARNING: Do not use, or allow the use of the products in the catalogue, unless the user has read and understands the applicable instructions and product warnings. Information available upon request.

Sling Angle

Sling angle (also called angle of loading) is the angle measured between a horizontal plane and the sling leg or body. This angle is very important and can have a dramatic effect on the rated capacity of the sling (see illustration below) . As illustrated at right, when this angle decreases, the load on each leg increases. This principle applies whether one sling is used to pull at an angle, in a basket hitch, or for multilegged bridge slings. Sling angles of less than 30° shall not be used.

Angles and Load

Angles and Stress

How do you carry two buckets of water? These illustrations typify the stresses imposed on slings when the legs are attached to the load at various angles.

Load Angle Factor

Sling Angle Load Angle

Degrees(A°) Factor =L/H

90 1.00

60 1.155

50 1.305

45 1.414

30 2.00

LOAD ON EACH LEG OF SLING=

(Load ÷2) ×LOAD ANGLE FACTOR

ANSI B30.9 recommends against the use of a horizontal sling angle smaller than 30°.

WARNING: Do not use, or allow the use of the products in the catalogue, unless the user has read and understands the applicable instructions and product warnings. Information available upon request.

Hot Tags: wire rope slings, flemish eye splice, flemish loop splice, China flemish eye splice, single part body, stainless steel wire rope sling, stainless steel screw wire, steel wire rope, high quality wire rope slings, wire rope slings China supplier, wire rope slings China manufacturer, wire rope slings China exporter, wholesale wire rope slings, low price wire rope slings

Other related products:

Factory & Package Show:

English

English