Jaw & Jaw Double Direction Screw Type Hot Cast Anchor, Fork Lug Double Direction Screw Type Hot Cast Anchor, Fork Lug Bidirectional Screw Type

- Dawson Group Ltd. - China Manufacturer, Supplier, Factory

High-strength steel wire cables for engineering use are divided into semi-parallel hot-extruded polyethylene steel wire cables and parallel steel wire cable strands.

The semi-parallel hot-extruded polyethylene steel wire cable is made of high-strength galvanized or zinc-aluminum alloy steel wires, closely arranged in a regular hexagon or a missing corner hexagon, twisted slightly with a left-hand twist, and then wrapped with a polyester fiber tape and wrapped outside the steel wire. Hot extruded high-density polyethylene sheathing forms the steel wire bundles. Anchors are installed at both ends of the steel wire bundle by casting, and the final tensile member is formed. Mainly used in cable-stayed bridges, arch bridges, suspension bridge slings, railway stations, airports, structures

Prestressed structures such as sports stadiums and coal sheds, product specifications are φ5x7~φ5x649, φ7x7~φ7x649, and the maximum diameter is φ229mm.

Parallel steel wire rope strands are composed of several high-strength galvanized or zinc-aluminum alloy steel wires, arranged in parallel groups in a regular hexagonal shape, and wrapped around binding tape at certain distances to form rope strands. Anchors are installed at both ends of the cable strands by casting, and the final tensile member is formed. Mainly used in suspension bridge main cables, product specifications are 61 wire, 91 wire, 127 wire and 169 wire.

Hot Cast Anchor

●Execute GB/T18365-2018 (Hot-extruded polyethylene high-strength steel wire cables for Kola Bridge).

●The structure consists of a cable body and anchors at both ends. The anchor consists of a fixed end and an adjusting end.

●Scope of application: sports venues, convention and exhibition centers, etc. Easy to adjust and strong in use.

●φ5mm series σb≥ 1670MPa

Product parameters

| Specifications | Cable body diameter (mm) | Inner opening A (mm) | Outer opening B (mm) | End distance C (mm) | Fork lug depth E (mm) | Pin diameter F (mm) | Lug plate width G (mm) | Adjustment amount T (mm) | Breaking force (KN) |

| Φ5×7 | 22 | 25 | 55 | 45 | 70 | 29 | 70 | 50 | 230 |

| Φ5×13 | 30 | 35 | 75 | 61 | 85 | 39 | 95 | 50 | 426 |

| Φ5×19 | 40 | 40 | 85 | 73 | 110 | 46 | 114 | 50 | 623 |

| Φ5×31 | 45 | 50 | 105 | 95 | 130 | 59 | 148 | 50 | 1017 |

| Φ5×37 | 50 | 55 | 115 | 103 | 140 | 64 | 162 | 80 | 1213 |

| Φ5×55 | 55 | 65 | 135 | 126 | 165 | 78 | 200 | 80 | 1804 |

| Φ5×61 | 59 | 70 | 145 | 133 | 175 | 83 | 210 | 80 | 2001 |

| Φ5×73 | 63 | 75 | 155 | 145 | 190 | 89 | 228 | 80 | 2393 |

| Φ5×85 | 65 | 80 | 165 | 156 | 205 | 96 | 248 | 80 | 2787 |

| Φ5×91 | 69 | 85 | 175 | 160 | 210 | 98 | 252 | 80 | 2984 |

| Φ5×109 | 72 | 90 | 185 | 175 | 225 | 108 | 280 | 100 | 3574 |

| Φ5×121 | 75 | 95 | 195 | 185 | 240 | 114 | 295 | 100 | 3968 |

| Φ5×127 | 79 | 100 | 205 | 190 | 245 | 116 | 300 | 100 | 4165 |

| Φ5×139 | 82 | 105 | 215 | 198 | 255 | 122 | 315 | 100 | 4557 |

| Φ5×151 | 83 | 110 | 225 | 205 | 260 | 127 | 325 | 100 | 4952 |

| Φ5×163 | 88 | 115 | 235 | 215 | 270 | 132 | 340 | 100 | 5345 |

| Φ5×187 | 92 | 120 | 245 | 230 | 295 | 142 | 365 | 100 | 6132 |

| Φ5×199 | 94 | 120 | 250 | 237 | 300 | 146 | 375 | 100 | 6525 |

| Φ5×211 | 98 | 125 | 260 | 243 | 300 | 148 | 385 | 100 | 6919 |

| Φ5×223 | 100 | 135 | 275 | 250 | 315 | 154 | 400 | 100 | 7312 |

| Φ5×241 | 102 | 140 | 285 | 265 | 325 | 165 | 420 | 100 | 7902 |

| Φ5×253 | 106 | 140 | 290 | 275 | 340 | 172 | 435 | 100 | 8296 |

| Φ5×265 | 110 | 145 | 295 | 282 | 340 | 175 | 445 | 120 | 8689 |

| Φ5×283 | 112 | 145 | 300 | 290 | 355 | 180 | 460 | 120 | 9280 |

| Φ5×301 | 116 | 155 | 315 | 300 | 365 | 186 | 475 | 120 | 9870

|

note:

1. The opening (A) and adjustment amount (T) of the anchor can be appropriately adjusted according to the needs of the project.

2. The size of Φ7 series anchors can be replaced by the size of Φ5 series anchors according to the breaking load.

Products Show:

Other Related Products:

Instructions for use of cable

Instructions for using the cable:

01

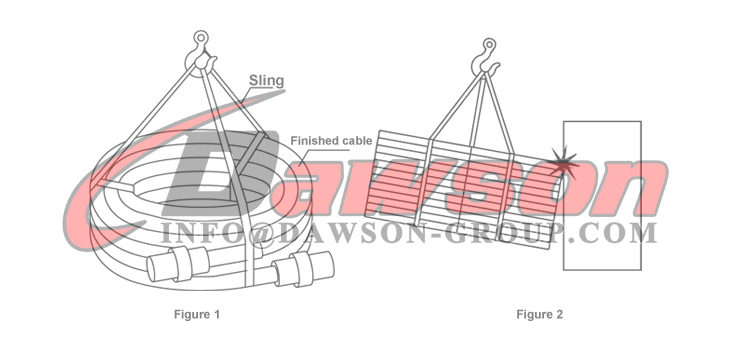

After the cable product arrives at the designated location, it must be hoisted with fiber tape to protect the surface of the cable and the packaging from damage. The hoisting method adopts three-point hoisting, and the hoisting process needs to be carried out with care. (See Figure 1) During the lifting process, the cable should be prevented from colliding with other objects, causing damage to the cable. (See Figure 2)

The storage location for cable products should be dry, with the bottom padded with sleepers and completely covered with rain-proof cloth.

02

The storage location for cable products should be dry, with the bottom padded with sleepers and completely covered with rain-proof cloth. When stacking stay cables, sleepers should be used to cushion each layer of stay cables, and they should be stacked neatly, with no more than two bundles at most (see Figure 3).

03

The diameter of the cable is less than 50mm. The cable with a short length (less than 10m) can be directly hoisted and released by a crane (the cable should be left for a period of time to release the internal stress after the cable is released). The diameter is greater than 50mm and the length is longer. It is advisable to use a special cable tray to place the cable (see Figure 4). The main cable should be placed using a special cable tray (Figure 5).

04

Before placing the cables, steel bars and other hard sharp objects at the construction site should be cleaned up; avoid contact between the cable body and the ground. Smooth rubber rollers should be laid on the ground, and vertical protective rollers should be set up to ensure that the cable body is not scratched by hard objects on the ground during construction. .

05

During the pulling process of the cable, necessary special lifting clamps and traction tools must be used. The clamps are lined with rubber washers and then fixed on the surface of the cable body. It is strictly prohibited to directly bundle the steel wire rope on the surface of the steel cable sheath to avoid collision between the steel rope and other steel components (see Figure 6).

06

The packaging material wrapped around the cable is a protective layer that prevents the cable from direct contact with the outside world. It can also prevent contact scratches on the cable during transportation and release. At the same time, it also prevents external debris from contaminating the surface of the colored cable body after the cable is hung. Therefore, it is recommended not to open the packaging before the completion of the project. It is best to remove it after the completion of the project to ensure that the colored PE cable is intact and the color is intact. consistent.

07

When adjusting the cable tension, a special wrench or tool should be used to adjust the anchor, and a pad should be added between the two. It is strictly forbidden to use chain pliers, vise and other tools for direct loading to prevent damage to the surface protective layer.

08

The surface of the cable anchors is electro-galvanized before leaving the factory. Each batch of cables should be installed as soon as possible after arriving at the site. After installation, all exposed anchors of the cables should be repainted (painted). The painting method can be the same as that of the steel structure. Anti-corrosion grease should be applied to the exposed threaded parts, and the joints should be protected with sealing silicone to prevent corrosion. Ensure the protective performance and service life of the cable.

09

For high vanadium coated cables, the cable body will be tightened with iron wires before leaving the factory. The iron wires should not be removed before installation and tensioning to prevent skipping or drumming of the cable body.

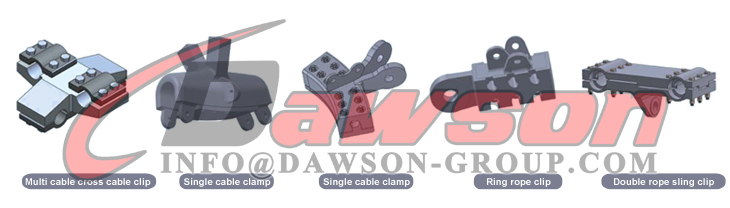

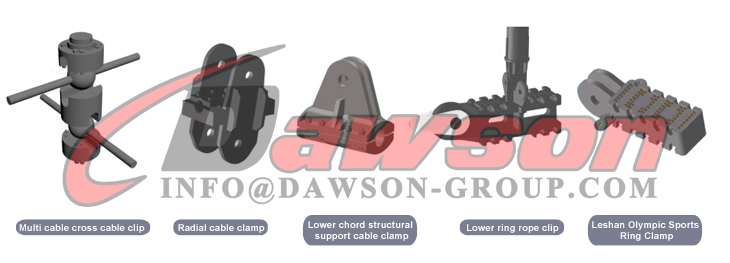

Cable Fittings:

Health Monitoring

System Structure

Description of main features of the system

01 System measurement accuracy: 1.5%F.S;

02 Sensor installation method: installed inline at each anchor plate, meeting the IP67 protection level, and realizing the function of the rigging's own measuring device;

03 Sensor calibration method: The rigging is calibrated before leaving the factory, and no calibration is required on site;

04 The collection equipment is installed on the sensor side and connected through wired cables. The collection equipment is wirelessly transmitted to the network management gateway, and the gateway transmits it to the cloud platform through the GPRS network for display, storage and query, and the data collection granularity can be set;

05 The system can automatically complete remote data transmission. The cloud platform center processes and analyzes the measured data, and can realize the function of sending detection data reports and over-value warning information to the client. It has strong compatibility, and the measurement end, collection end, and platform can all implement standardized data interfaces to facilitate customer data application or development.

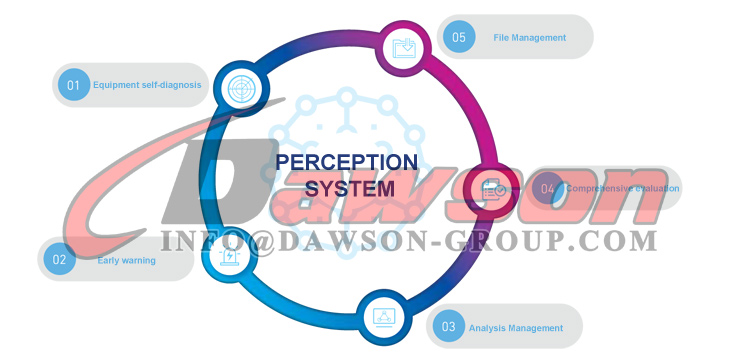

The entire system is divided into perception layer, collection and transmission layer, cloud processing layer and application layer. The sensing layer installs sensors through welding to realize real-time monitoring of the load stress of the rigging. The acquisition device collects signals and transmits them to the cloud platform through the ZIGBEE/GPRS wireless network. The cloud platform center processes and analyzes the uploaded data. Finally, Test results, data reports, and early warning confidence are sent to the client.

Software Application

The software application is mainly based on the rigging requirements, briefly sorting out the framework and function points of existing localized products, cloud platforms, and considering the support for the rigging detection system. The system can provide a good human-computer interaction interface to facilitate user operation and has the following functions:

Perception System

Smart Cable

Cables are widely used in large structures such as large bridges and have very important social significance and economic value to the bridge operation department. Intelligent cables will generally adopt institutional health detection technology that installs the detection system on the bridge after the bridge is completed, leaping to the point where the detection system and the structural system are truly organically integrated.

Working Principle

The intelligent cable system consists of intelligent induction nuts, cable bodies and other cable components, collection and transmission equipment, cloud and application terminals. When the cable is stressed, strain can be induced on the cable nut and cable body, and the acquisition equipment can collect the data at the sensing end and transmit it to the cloud through wired or wireless transmission, so that the detection data can be directly viewed or processed.

Intelligent Cable Force Measurement Process

① Intelligent cable production → ② Intelligent cable calibration → ③ On-site installation and layout of cable and equipment → ④ Load monitoring, of which ① and ② are completed in the factory, and ③ and ④ are implemented at the construction site. The development of smart cables can realize the load detection of the cable during tensioning and long-term load monitoring after anchoring, and at the same time realize portable installation, which can meet the construction requirements of current structures.

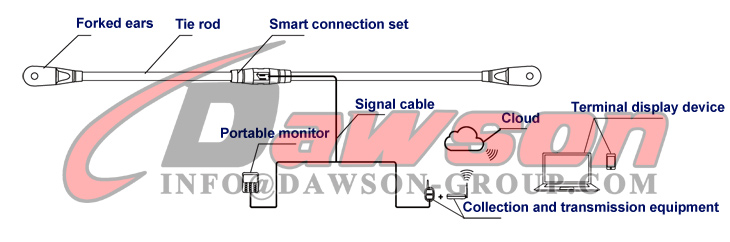

Smart Steel Tie Rod

Steel tie rods have the advantages of high strength, good toughness, economy and applicability, and have been widely used as direct units in prestressed steel structures. Whether the prestressed steel tie rods meet the design requirements during construction will be directly related to the load-bearing capacity and safety performance of the prestressed structure. Therefore, the detection and monitoring of its internal forces have become an important part of the construction stage. At present, the force measurement methods of steel tie rods mostly use the torque coefficient method or the hydraulic conversion method. The measurement results are affected by many factors, and the comprehensive factors are relatively large. It is difficult to meet the current construction requirements of prestressed steel structures. Smart steel tie rods are designed to realize the sensing and monitoring of structures through a set of smart steel tie rod systems. Provide effective evaluation data for construction personnel, construction and operation units, and colleagues on site Achieve convenient, fast, safe and effective installation.

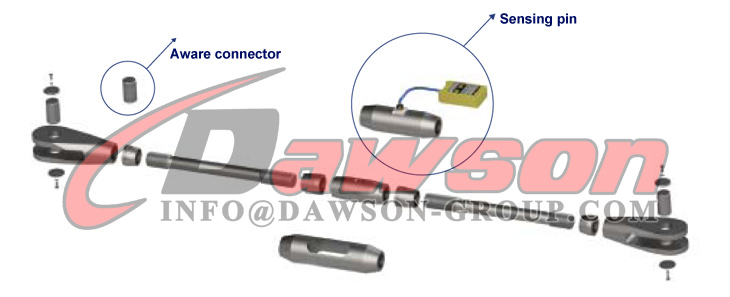

Working Principle

The smart steel tie rod system consists of steel tie rod components such as induction fork lug pins or smart connections, collection and transmission equipment, cloud, and application terminals. The sensing principle adopts principles such as vibrating wire and resistance. When the steel tie rod is stressed, it can be sensed on the fork lug pin or connecting sleeve. The data of the sensing section is collected through the acquisition and transmission equipment and transmitted to the cloud through wired or wireless transmission. On the application side, you can directly check the stress status of the steel tie rod or process the detection data.

Smart Steel Tie Rod Force Measurement Process

① Production and production of smart steel tie rods → ② Calibration of smart steel tie rods → ③ On-site installation and layout of steel tie rods and equipment → ④ Load monitoring, of which ① and ② are processed in the factory, and ③ and ④ are implemented at the construction site.

The development of smart steel tie rods can realize load detection of steel tie rods during tensioning and long-term load monitoring after installation, while also achieving portable installation, which can meet the construction requirements of current structures.

Fork lugs, tie rods, smart connection sleeves

Portable display signal cable cloud terminal display equipment

Collection and transmission equipment

Advantage comparison

1High compatibility

Intelligent rigging itself is a system that can be connected to other subsystems as a main system or integrated into other systems as a subsystem. It has high compatibility; traditional sensors have poor compatibility and are incompatible with many systems and have great limitations.

2 System implementation efficiency

The system can be quickly brought online without complicated wiring.

3 On-site installation efficiency

Intelligent sensors, cables and rigging adopt integrated equipment or installation, which does not affect the normal installation and use of rigging, and the system adopts a wireless distributed design. Traditional sensors require on-site technical guidance from professionals for installation, and no wiring is required on-site, reducing on-site implementation and maintenance costs.

Engineering Project Cases Catalogue Download:

Package and Factory Show:

English

English