DS-PA Series G100 Universal Direction Rotating Lifting Eye bolt

- Dawson Group Ltd. - China Manfacturer Supplier, Factory

Applicable Standards:EN ISO 12100:2010,EN ISO 3266:2010+A1:2015,EN 1677-4:2000+A1:2008

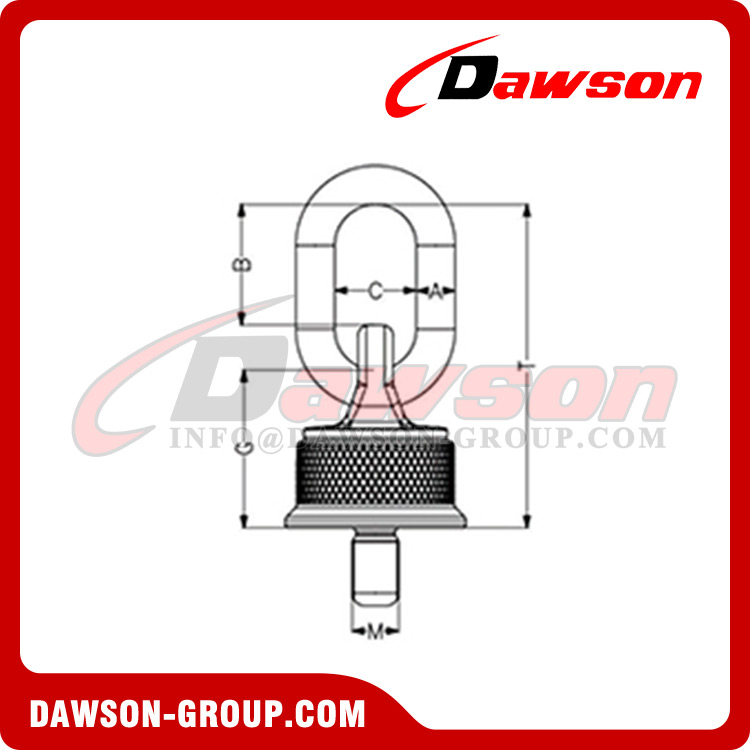

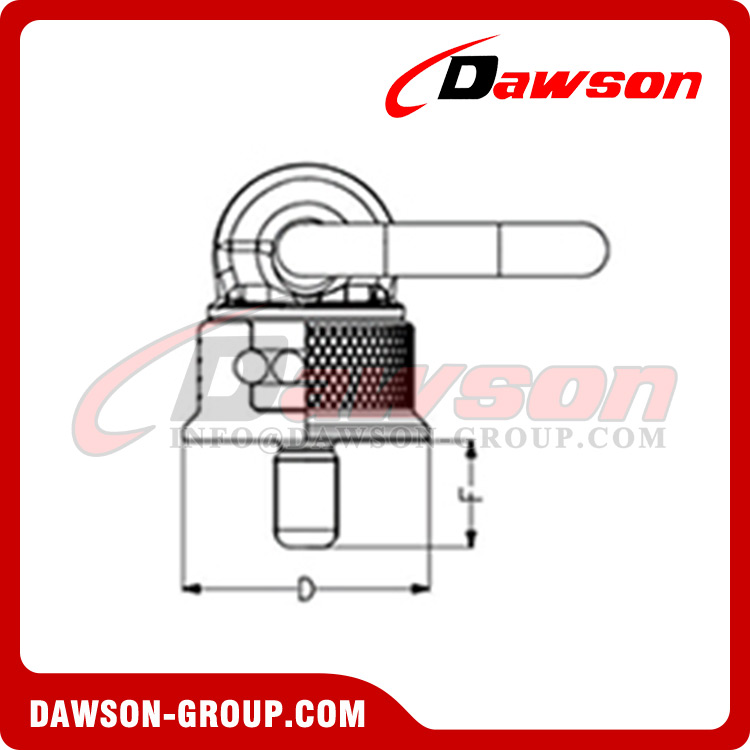

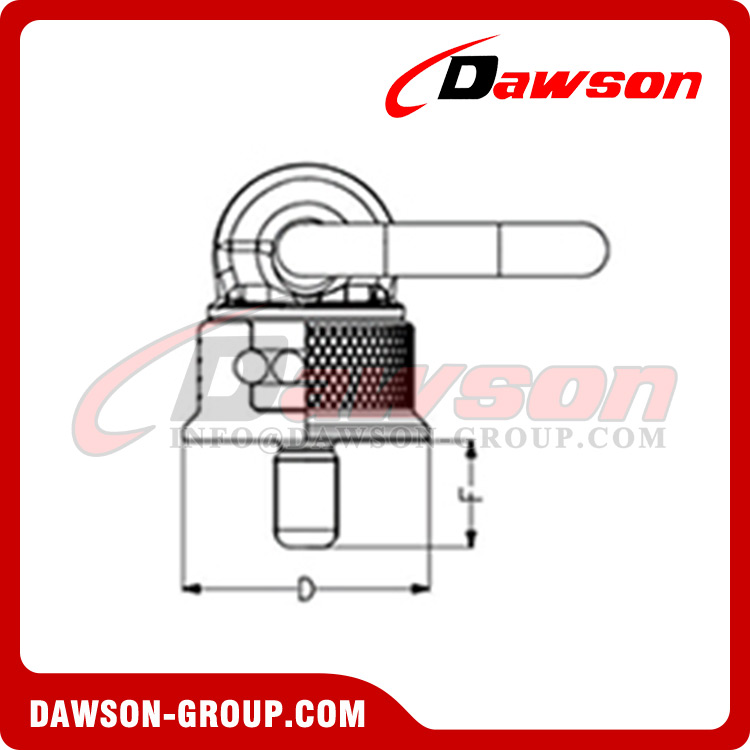

METRIC DIMENSION TABLE OF PRODUCTS

Product features

● With unique ball bearing design, the eye bolt can rotate 360° and turn 230° for lifting. Four times of safety factor shall be ensured in any force direction.

● The eye bolt is forged from G100 high-strength molybdenum alloy steel, and subject to quenching and tempering to achieve sufficient strength and toughness.

● The eye bolt is manufactured and tested in accordance with EN1677-4 and other relevant specifications. The products have been certificated for Euro Cert CE.

● All products can be traced for quality through the test reports.

● The metric thread of the eye bolt complies with DIN EN 13 (M-6g), the UNC thread complies with ASME/ANSI B18.3.1M (UNC-2A), and the threads are 100% tested by go-no go fixed gauges, and the outer diameter tolerance of the thread is accurate to 6g.

● The products are tested by magnetic particle to ensure that they are free of cracks.

● The products are subject to dynamic fatigue limit test for 20,000 times under 1.5 times of working limit load.

● The eye bolt base with circular knurled design is easy to install and remove.

● Some product are numbered, convenient for traceability.

Installation and use

● The thread hole is sufficiently long to ensure that the eye bolt thread is completely screwed in;

● The eye bolt thread is securely fastened and fitted tightly to the contact surface (screwed in manually; not allowed to be tightened with tools);

● When the loading ring is in the vertical lifting direction, the load can be reached.

● It can rotate under rated load. However, it is not suitable for permanent rotation at full load in 90° direction.

● Any operation shall be Any operation shall be performed in strict accordance with the product operation manual.

Acceptance Procedure

1、The overall dimensions shall be accepted according to the corresponding standards, without cracks and defects, and the specifications, bearing capacity and material code shall be indicated clearly on the eye bolt surface;

2、Acceptance of eye bolt thread: visually inspect the thread appearance which should be intact and free of damage, and test with the thread ring gauge (drift diameter gauge, no-go gauge), with an accuracy of 6g.

3、The thread axis of the eye bolt shall be perpendicular to the bearing surface. Rotate a go gauge to fit the thread root with the bearing surface without clearance, that is, the perpendicularity is acceptable;

4、For acceptable eye bolts, certificate of delivery or detailed written test report shall be provided for archival purposes.

Restrictions on Operation

1、Operating temperature range: - 40 ℃ to 400 ℃ (please consult the manufacturer if the actual operating temperature is higher than 200 ℃);

2、Please keep the eye bolts away from acid, alkali or its vapor. For any application in a chemical environment, please contact the Technology Department of DAWSON.

3、Warning: Do not exceed the maximum safe lifting load.

Precautions for Installation and Operation

1、The maximum lifting weight (safe working load at limit) of the eyebolt is only applicable to the cases where the eye bolt is installed on steel, cast steel or non-cast iron parts;

2、The area around the threaded hole shall be kept smooth and the hole depth sufficient to fully lock the bolt;

3、The eye bolt shall be screwed in to make the bearing surface closely fit, but not be tightened forcefully by tools; if not screwed in place, the eye bolt will be deformed or broken;

4、Please hoist the goods according to the angle of the safe working load of the eye bolt. The eye bolts shall be installed at different positions according to specific lifting mode. Do not move the center of gravity during lifting.

5、Please install the eye bolts according to the number of lifting points designed on the work piece, and the number of lifting points cannot be reduced.

6、Please slowly hoist the goods to avoid impact caused by fast lifting.

7、No illegal operation is allowed.

● The lifting eye bolt structure is changed;

● The lifting eye bolt is subjected to lateral force;

● The lifting eye bolt is significantly deformed and severely worn;

● The thread is damaged;

● The lifting eye bolt is not fitted with the supporting surface;

● Lifting method is excluded in the marked range.

Maintenance and Inspection

1、The enterprise is required to conduct an internal safety inspection every quarter each year, and make inspection records;

2、One comprehensive inspection shall be performed by professionals each year, and inspection records shall be made;

3、The eye bolt surface shall be cleaned so that it can be clearly inspected;

4、Pay attention to signs that may affect the safety and function during inspection, including thread defect, crack, groove, deformation, obvious signs of high temperature, etc.; the longitudinal section wear is higher than 10%.

5、If the signs that may affect the safety and function of the eye bolt are found in the inspection, the eye bolt should be eliminated and scrapped;

WARN

·There is a risk of falling off of heavy objects under abnormal assembly and hoisting operations.

·Falling heavy objects can cause serious injury or even death.

·During installation and visual inspection before each use,pay special attention to corrosion, Wear,cracks or deformation. Make sure that the thread of the bolt matches the threaded hole.

·Please use original DAWSON parts.

Hot tags: eye bolt,lifting eye bolt,rotating lifting eye bolt,universal direction rotating lifting eye bolt,g100 rotating lifting eye bolt,grade 100 rotating lifting eye bolt,lifting points,universal rotating lifting eye bolt,g100 universal rotating lifting eye bolt,grade 100 universal rotating lifting eye bolt

Other related products:

Application of Eye Bolts:

Factory & Package Show:

English

English