DAWSON Heavy Duty Snatch Block, Lifting Pulley Blocks, Wire Rope Pulley

- Dawson Group Ltd. - China Manufacturer, Factory, Supplier

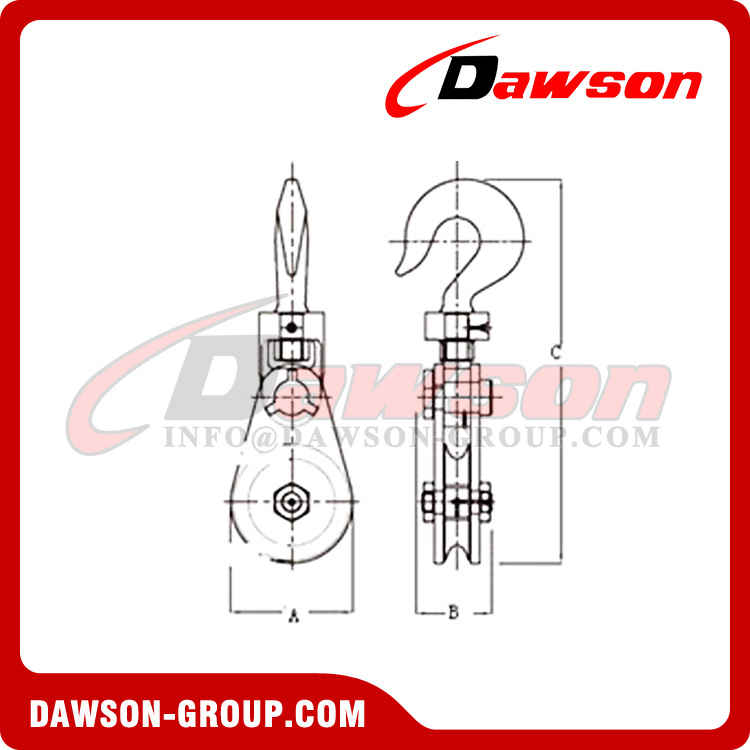

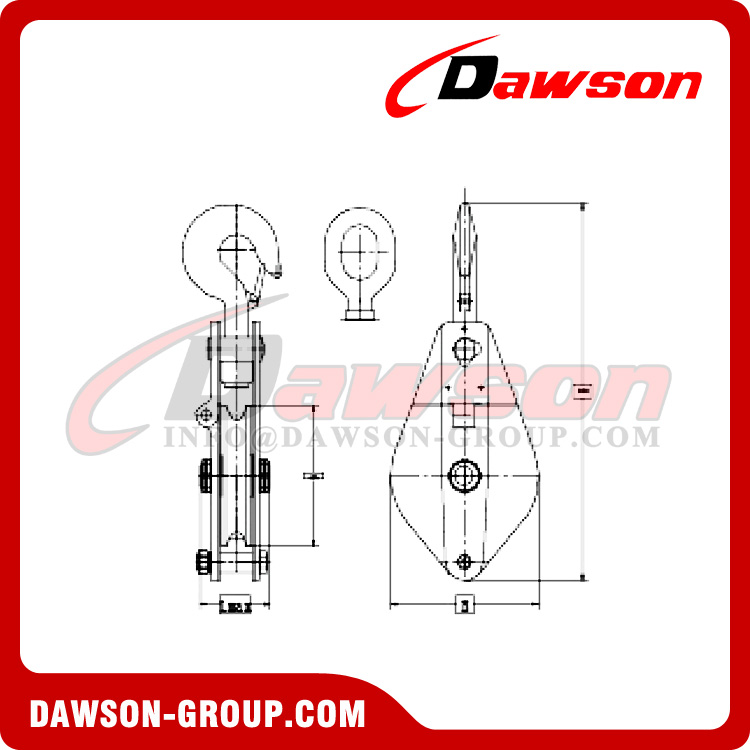

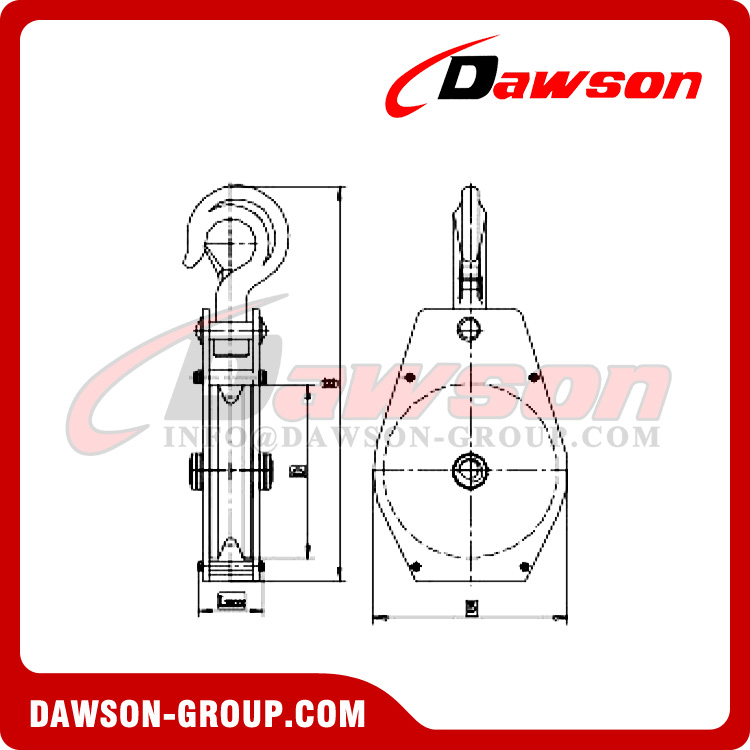

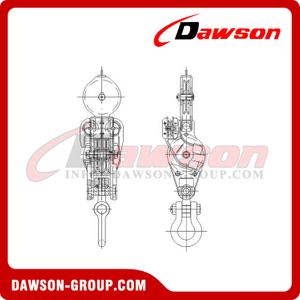

Dawson Heavy Duty Snatch Block with Hook (forged steel sheave)

| Item No. | Working Load | Pulley Diameter | Applicable wire rope | D | W | H | L | Unit weight |

| TYPE | (Ton) | (in.) | (mm) | (mm) | (mm) | (mm) | (mm) | (KG) |

| 2111-3’’×2T | 2 | 3 | 7--9 | 75 | 76 | 54 | 237 | 2.2 |

| 2111-4.5’’×4T | 4 | 4.5 | 10--12 | 115 | 116 | 71 | 355 | 6.8 |

| 2111-6’’×8T | 8 | 6 | 16--19 | 152 | 155 | 90 | 495 | 12.2

|

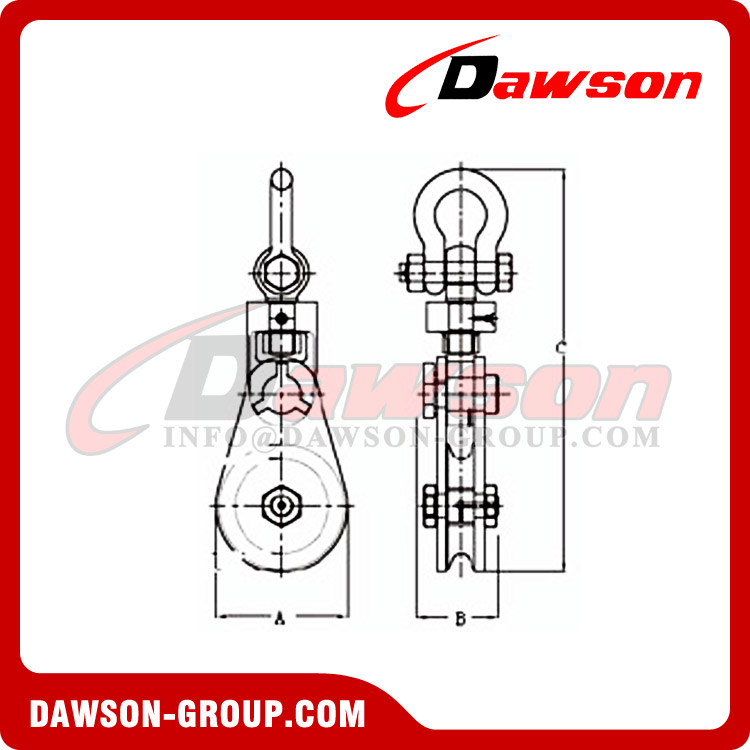

Heavy Duty Snatch Block with Shackle(forged steel sheave)

| Item No. | Working Load | Pulley Diameter | Applicable wire rope | D | W | H | L | Unit weight |

| TYPE | (Ton) | (in.) | (mm) | (mm) | (mm) | (mm) | (mm) | (KG) |

| 2121-3’’×2T | 2 | 3 | 7--9 | 75 | 76 | 54 | 237 | 2.3 |

| 2121-4.5’’×4T | 4 | 4.5 | 10--12 | 115 | 116 | 71 | 355 | 6.7 |

| 2121-6’’×8T | 8 | 6 | 16--19 | 152 | 155 | 90 | 495 | 13.6

|

Technology advantages:

1. All key parts are forged with high-strength alloy steel and hear treated.

2. 4:1 safe factor, CE certificate, and meets EN 13157, and ASME 30.26

3. Equipped with carbon steel sheave and grease nipple, convenient for operating and repairing, and also extending service life.

4. DS-JDB self-lubricating sliding bearing, conveniently, does not need to be greased quiet often, the national patent.

5. Permanent product batch no., blocks can be tracking easily.

6. Equipped with forged steel sheave or hot-rolled steel sheave.

7. Customized according to the clients' requirements.

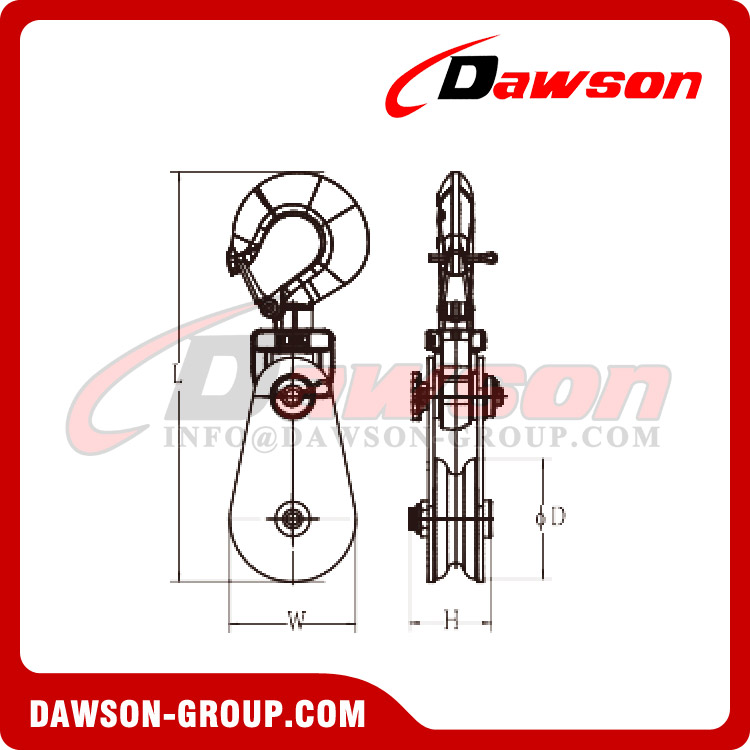

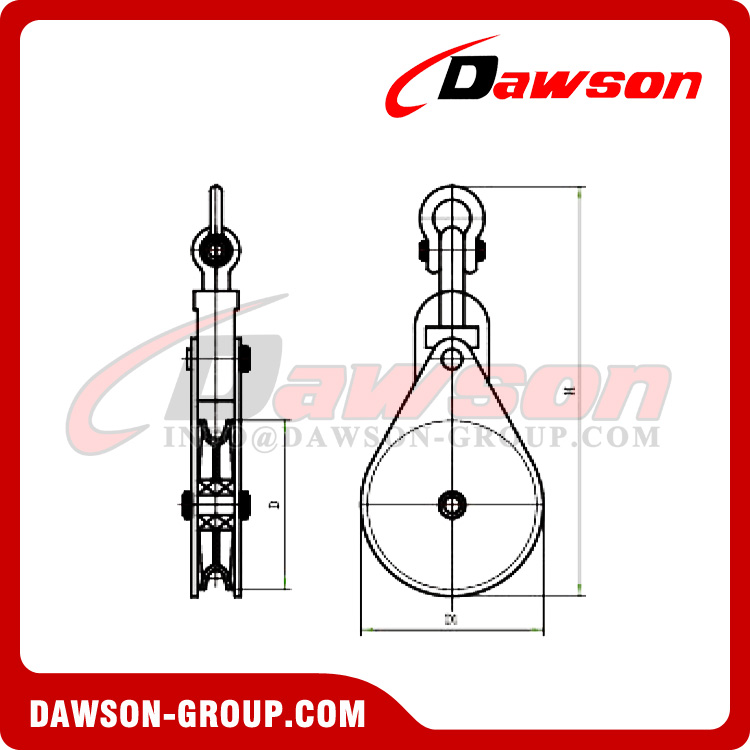

Heavy Duty Snatch Block with Hook(Hot-rolled steel sheave)

| Item No. | Working Load | Pulley Diameter | Applicable wire rope | D | W | H | L | Unit weight |

| TYPE | (Ton) | (in.) | (mm) | (mm) | (mm) | (mm) | (mm) | (KG) |

| 2111-6’’×8T | 8 | 6 | 16-19 | 152 | 155 | 90 | 495 | 12.2 |

| 2111-6’’×10T | 10 | 6 | 16-19 | 152 | 155 | 95 | 520 | 17 |

| 2111-8’’×8T | 8 | 8 | 20-22 | 202 | 205 | 103 | 551 | 21 |

| 2111-10’’×10T | 10 | 10 | 24-26 | 254 | 260 | 115 | 562 | 35 |

| 2111-10’’×12T | 12 | 10 | 24-26 | 254 | 260 | 115 | 705 | 39 |

| 2111-10’’×15T | 15 | 10 | 19-22 | 254 | 260 | 135 | 713 | 56 |

| 2111-10’’×20T | 20 | 10 | 25-29 | 254 | 257 | 150 | 777 | 60 |

| 2111-12’’×12T | 12 | 12 | 24-26 | 304 | 307 | 133 | 801 | 58 |

| 2111-12’’×15T | 15 | 12 | 19-22 | 304 | 307 | 135 | 804 | 60 |

| 2111-12’’×20T | 20 | 12 | 25-29 | 304 | 307 | 150 | 833 | 68

|

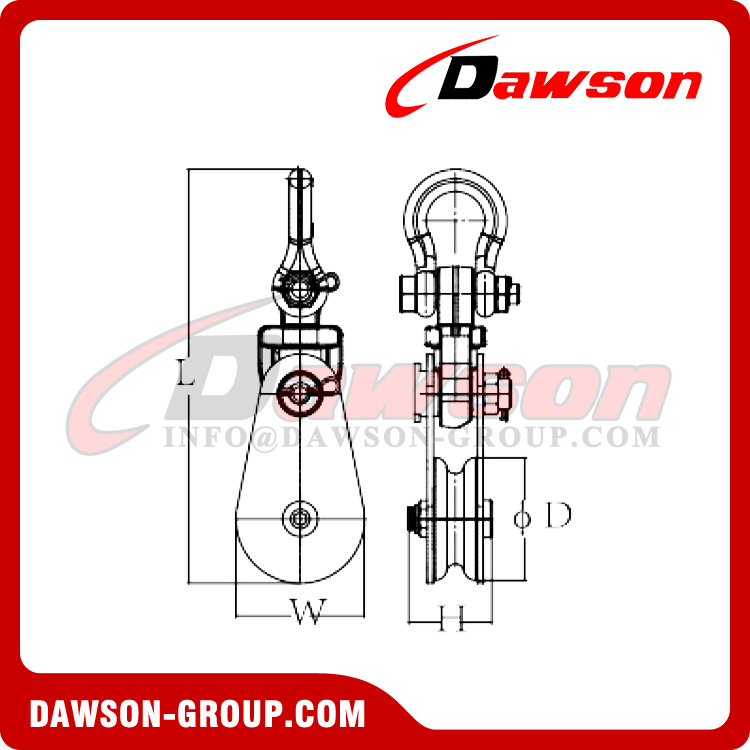

Heavy Duty Snatch Block with Shackle(Hot-rolled steel sheave)

| Item No. | Working Load | Pulley Diameter | Applicable wire rope | D | W | H | L | Unit weight |

| TYPE | (Ton) | (in.) | (mm) | (mm) | (mm) | (mm) | (mm) | (KG) |

| 2121-6”×8T | 8 | 6 | 16-19 | 152 | 155 | 90 | 495 | 13.6 |

| 2121-6’’×10T | 10 | 6 | 16-19 | 152 | 155 | 95 | 520 | 16 |

| 2121-8’’×8T | 8 | 8 | 20-22 | 202 | 205 | 103 | 560 | 19.3 |

| 2121-10’’×10T | 10 | 10 | 24-26 | 254 | 260 | 115 | 679 | 35 |

| 2121-10’’×12T | 12 | 10 | 24-26 | 254 | 260 | 115 | 685 | 40 |

| 2121-10’’×15T | 15 | 10 | 24-26 | 254 | 260 | 135 | 713 | 54 |

| 2121-10’’×20T | 20 | 10 | 25-29 | 254 | 257 | 150 | 777 | 56 |

| 2121-12’’×12T | 12 | 12 | 24-26 | 304 | 307 | 133 | 767 | 56 |

| 2121-12’’×15T | 15 | 12 | 24-26 | 304 | 307 | 135 | 788 | 58 |

| 2121-12’’×20T | 20 | 12 | 25-29 | 304 | 307 | 150 | 833 | 62 |

| 2121-14’’×22T | 22 | 14 | 29-32 | 355 | 360 | 140 | 952 | 112 |

| 2121-16’’×22T | 22 | 16 | 29-32 | 406 | 410 | 140 | 1019 | 122 |

| 2121-16’’×30T | 30 | 16 | 32-35 | 406 | 415 | 155 | 1128 | 164 |

| 2121-20’’×30T | 30 | 20 | 32-35 | 508 | 515 | 184 | 1230 | 213 |

| 2121-24’’×50T | 50 | 24 | 38-42 | 609 | 615 | 189 | 1330 | 340 |

| 2121-30’’×85T | 85 | 30 | 46-50 | 762 | 765 | 236 | 1910 | 590 |

| 2121-32’’×100T | 100 | 32 | 68-72 | 812 | 824 | 310 | 2100 | 650 |

| 2121-16’’×120T | 120 | 35 | 78-82 | 889 | 900 | 330 | 2350 | 700

|

Technology advantages(hot-rolled steel sheave):

1.All key parts are forged with high-strength alloy steel and hear treated.

2.4:1 safe factor, CE certificate, and meets EN 13157, and ASME 30.

3.Equipped with carbon steel sheave and grease nipple, convenient for operating and repairing, and also extending service life.

4.DS-JDB self-lubricating sliding bearing, conveniently, does not need to be greased quiet often, the national patent.

5.Permanent product batch no., blocks can be tracking easily.

6.Equipped with forged steel sheave or hot-rolled steel sheave.

7.Customized according to the clients' requirements.

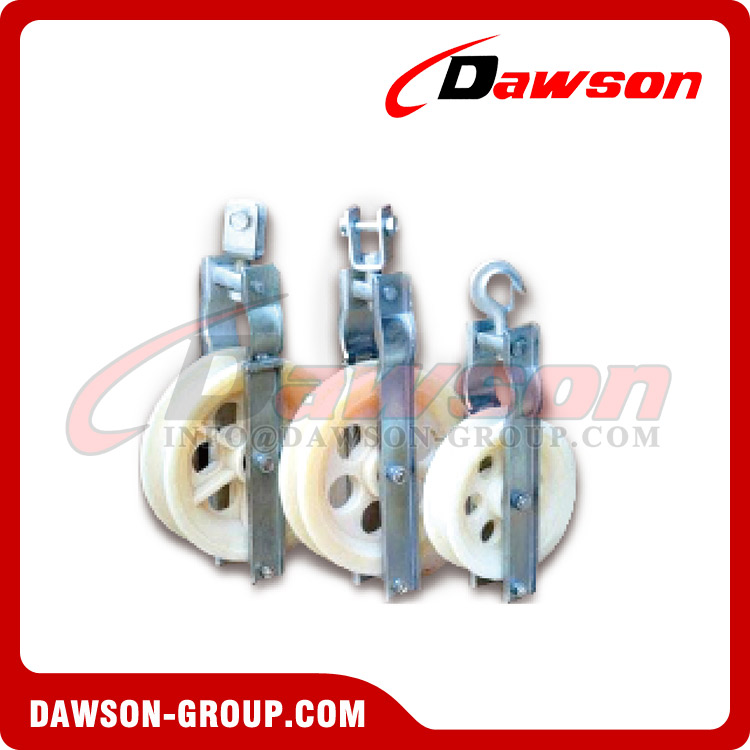

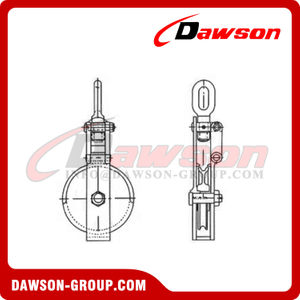

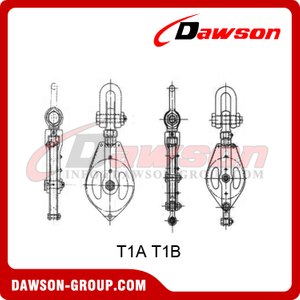

DS-HY DS-HQ Series Single Wheel Block, Multi-Wheel Blocks

Solution of DS-HY Series General Block:

DS-HY series has been researched and developed by our company and the Hoisting Machinery Research Institute of the Machinery Department together according to the characteristics of the forestry field. Different from DS-HQ series,”DS-HY” series of pulley block is equipment with rolling bearing, so as to turn more easily, and be faster.It has been derived according to the original national standard JB/T9007.2-1999:, which has filled in the gap of block industry in China.

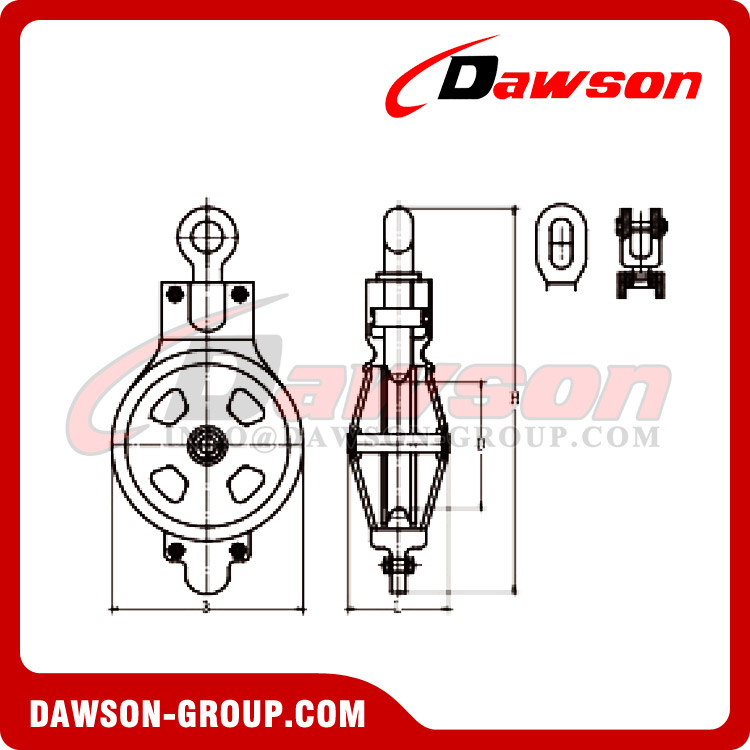

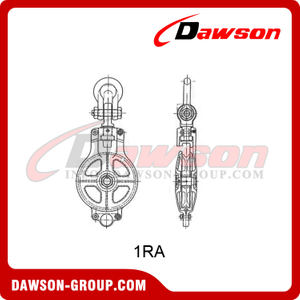

DS-HY、DS-HQ Series Single Wheel Block

Name

| Size | Rated Slinging Load(TON) | Suitable Steel Wire Diameter(mm) | Sheave Diameter(mm) | Packaging box volume(cm3) | Qty.per box(set) |

| Single pulley hook(chain/ring)block | DS-HYG(L)K1-0.5 | 0.5 | 5-7 | 85 | 40×40×17 | 20 |

| DS-HYG(L)K1-1 | 1 | 7-11 | 105 | 37×37×14 | 10 |

| DS-HYG(L)K1-2 | 2 | 11-14 | 135 | 40×40×17 | 6 |

| DS-HYG(L)K1-3.2 | 3.2 | 12.5-15.5 | 160 | 45×24×16 | 3 |

| DS-HYG(L)K1-5 | 5 | 15.5-18.5 | 202 | 55×32×12 | 2 |

| DS-HYG(L)K1-8 | 8 | 20-23 | 260 | Plastic blister packaging | 1 |

| DS-HYG(L)K1-10 | 10 | 23-24.5 | 280 | Plastic blister packaging | 1 |

| DS-HYG(L)K1-16 | 16 | 28-31 | 345 | Plastic blister packaging | 1 |

| DS-HYG(L)K1-20 | 20 | 31-35 | 390 | Plastic blister packaging | 1 |

| DS-HY(HQ)G(L)K1-32 | 32 | 35-38 | 490 | Plastic blister packaging | 1 |

| DS-HY(HQ)G(L)K1-50 | 50 | 40-43 | 560 | Plastic blister packaging | 1

|

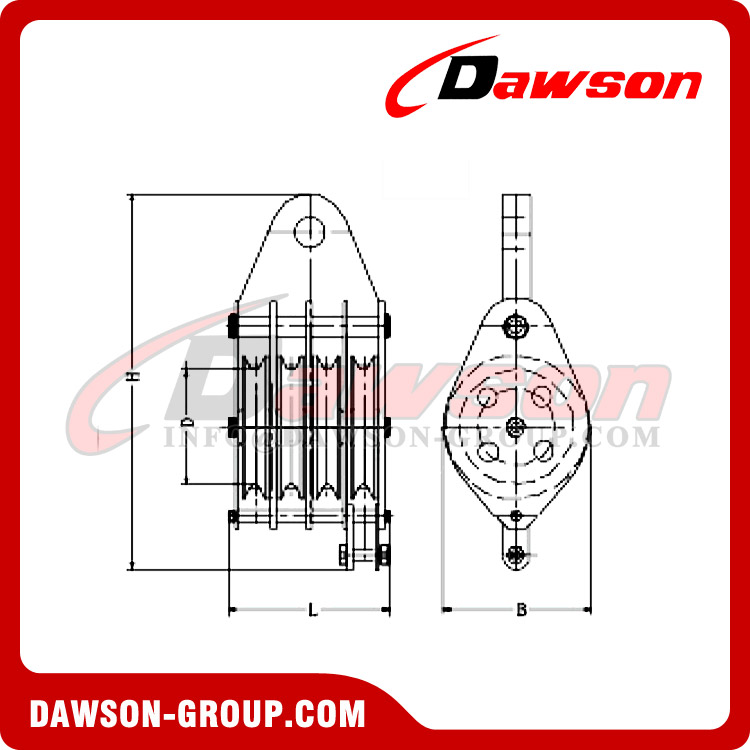

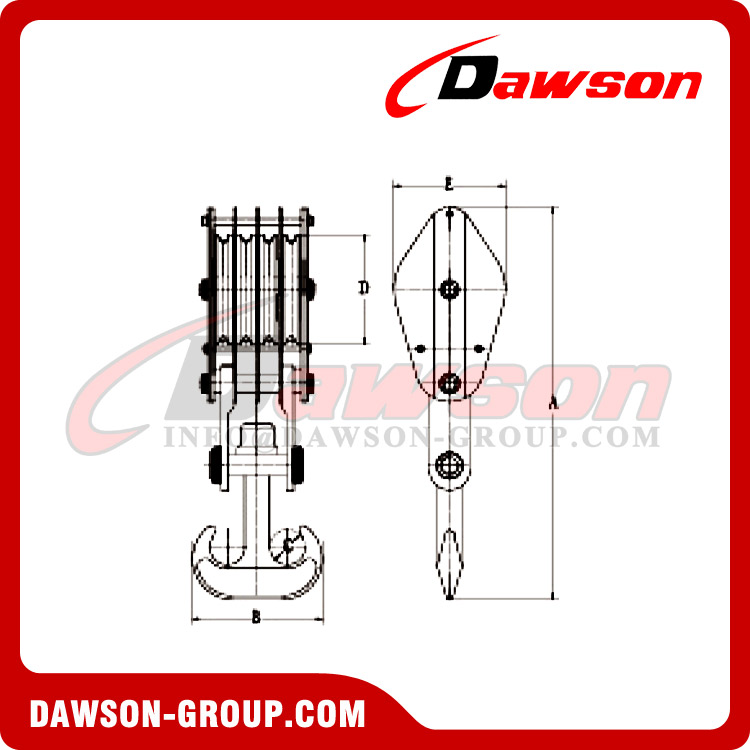

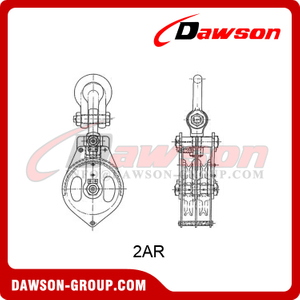

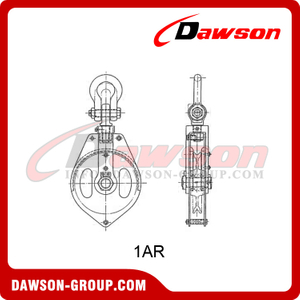

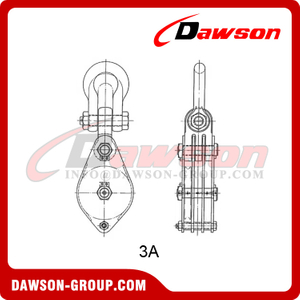

DS-HY、DS-HQ Series Muti-Wheel Block

DS-HY、DS-HQ Series Muti-Wheel Block

Name

| Size | Rated Slinging Load(TON) | Suitable Steel Wire Diameter(mm) | Sheave Diameter(mm) | Packaging box volume(cm3) | Qty.per box(set) |

| Double-sheave hook (swinging ring) block | DS-HYG(D)2-1 | 1 | 5-7 | 85 | 37×37×14 | 10 |

| DS-HYG(D)2-2 | 2 | 7-11 | 106 | 40×40×17 | 8 |

| DS-HYG(D)2-3.2 | 3.2 | 11-14 | 135 | 45×24×16 | 4 |

| DS-HYG(D)2-5 | 5 | 12.5-15.5 | 160 | 45×24×16 | 4 |

| DS-HYG(D)2-8 | 8 | 15.5-18.5 | 202 | Plastic blister packaging | 1 |

| DS-HYG(D)2-10 | 10 | 17-20 | 230 | 1 |

| DS-HYG(D)2-16 | 16 | 23-24.5 | 300 | 1 |

| DS-HYG(D)2-20 | 20 | 26-28 | 345 | 1 |

| DS-HQD2-32 | 32 | 31-35 | 390 | 1 |

| Three-sheave (swinging ring) block | DS-HYG(D)3-3.2 | 3.2 | 7.7-11 | 105 | 45×24×16 | 4 |

| DS-HYG(D)3-5 | 5 | 11-14 | 135 | 45×24×16 | 2 |

| DS-HYG(D)3-8 | 8 | 12.5-15.5 | 160 | Plastic blister packaging | 1 |

| DS-HYG(D)3-10 | 10 | 15.5-18.5 | 202 | 1 |

| DS-HYG(D)3-16 | 16 | 17-20 | 230 | 1 |

| DS-HYG(D)3-20 | 20 | 20-23 | 260 | 1 |

| DS-HQD3-32 | 32 | 26-28 | 345 | 1 |

| DS-HQD3-50 | 50 | 31-35 | 435 | 1 |

| Four-sheave (swinging ring) block | DS-HYD4-8 | 8 | 11-14 | 135 | Plastic blister packaging | 1 |

| DS-HYD4-10 | 10 | 12.5-15.5 | 160 | 1 |

| DS-HYD4-16 | 16 | 15.5-18.5 | 202 | 1 |

| DS-HYD4-20 | 20 | 17-20 | 230 | 1 |

| DS-HQD4-32 | 32 | 23-24.5 | 300 | 1 |

| DS-HQD4-50 | 50 | 28-31 | 390 | 1 |

| Five-sheave (swinging ring) block | DS-HYD5-20 | 20 | 15.5-18.5 | 202 | Plastic blister packaging | 1 |

| DS-HQD5-32 | 32 | 20-23 | 260 | 1 |

| DS-HQD5-50 | 50 | 26-28 | 345 | 1 |

| DS-HQD5-80 | 80 | 31-35 | 435 | 1 |

| Six-sheave (swinging ring) block | DS-HQD6-32 | 32 | 17-20 | 230 | Plastic blister packaging | 1 |

| DS-HQD6-50 | 50 | 23-24.5 | 300 | 1 |

| DS-HQD6-80 | 80 | 26-28 | 390 | 1 |

| DS-HQD6-100 | 100 | 31-35 | 435 | 1 |

| Eight-sheave (swinging ring) block | DS-HQD8-80 | 80 | 26-28 | 345 | Plastic blister packaging | 1 |

| DS-HQD8-100 | 100 | 28-31 | 390 | 1 |

| DS-HQD8-160 | 160 | 31-35 | 435 | 1 |

| DS-HQD8-200 | 200 | 34-38 | 490 | 1 |

| Ten-sheave (swinging ring) block | DS-HQD10-200 | 200 | 31-35 | 435 | Plastic blister packaging | 1

|

Technology advantages:

1. Rolling bearings are installed, thus the friction coefficient is small and the tackle rotates more flexibly.

2. The main parts are made of alloy steel, which is superior to national safety standard.

3. The lubricant is filled up before assembling, the service life will be lengthened with more than 3 times than that of other general blocks.

DS-JDB Bronze Bearing Block, DS-JDB Embedded Solid Oil Bearing Lubricating Bearing, DS-JDB Series Mosaic Solid Lubrication Bearing Lifting Tackle Used for Hoisting Equipment Matching in Industrial, Mining, Infrastructure, Port and Wharf

Industry solutions:

The traditional metallurgical powder sleeve and copper sleeve are easy to wear and wear oil to affect the construction. According to the problems encountered by the users, the research center of Dawson Block is constantly experimenting. Finally, the DS-JDB embedded solid oil copper alloy sliding bearing with self lubrication, no oil injection and damping and wear resistance is developed, and its service life is more than 10 times of common metallurgical powder set, and it is another new invention in the industry.

Technological advantages:

DS-JDB inlaid solid oil and copper alloy sliding bearing have the advantages of reliable performance and long service life. Compared with ordinary bronze bushing, the wear resistance is more than 10 times that of the bronze bushing.

Comparison between DS-JDB inlaid solid oil bearing copper alloy sliding bearing and bronze sleeve

| Experimental pressure 24.5N/mm2 |

| Model | Lubrication condition | Wear amount(mm) | (Time) |

| The copper sleeve | Oil lubrication | 0.125 | 100 |

| DS-JDB embedded solid oil bearing lubricating bearing | Self lubrication | 0.013 | 100

|

DS-MC Nylon Sheave Series Hoisting Block, Nylon Block, Lifting Pulley, Pulley Block

Industry solutions:

According to the needs of the hoisting belt in port, wharf and sea construction, the DS-MC nylon block has been developed with the R&D center of Dawson. The pulley has wide and narrow wheels, which is suitable for the demand of different hoisting belts.

The lifting sheave made of DS-MC nylon has the following characteristics

1. DS-MC nylon sheave has good wear resistance and self lubrication performance, and its wear life is 4-5 times higher than that of steel and iron sheaves.

2. Do not damage the dual material, more suitable for high-strength sling.

3. To meet a wide temperature range, can be used in the temperature range of 40 to 100 DEG C.

4. Can shock absorption, do not produce noise, smooth operation.

5. Light weight, corrosion resistance, non stick water and no rust. It is more suitable for port, dock and offshore operation.

6. The mechanical processing performance is good, the shape stability is high.

DS-MC Nylon Block Parameters

| External Dia (mm) | Inner Dia (mm) | Thickness(mm) |

| 200 | 40 | 37 |

| 230 | 45 | 40 |

| 260 | 45 | 46 |

| 280 | 50 | 46 |

| 320 | 75 | 65 |

| 330 | 60 | 55 |

| 350 | 60 | 90 |

| 450 | 80 | 90

|

DS-EB Engineering Block, Large Scale Hot Rolled Steel Wheel Pulley Block, Hot Rolled Steel Roller Skater, Hot-Rolled Steel Sheave Block

Industry solutions:

In the face of the traditional pulley sheave defects, Dawson design team decided to upgrade the sheave,the key component of determining the service life of the pulley. According to the international standard, and combining with China's JB/T9007.2-1999 standard, successfully developed the”single plate of hot rolled steel wheel heavy multi wheel lifting pulley, has been used in the Three Gorges Project, Qingdao port more than 1000 large projects.

Technique Advantages:

1. Hot rolled steel roller skater is the replacement product of tradition cast iron and cast steel roller skater. To avoid the common slide cast iron wheel easily broken phenomenon, is our company design center independently developed the patented products, to fill the domestic gap.

2. The product has the advantages of high pressure, large load, short production cycle, beautiful appearance, durable, safe and reliable.

3. The pulley of this product is a hot-rolled steel wheel made by advanced International technology. It has reasonable structure, high load, high bearing pressure and reduced friction with wire rope.

DS-WPB Wind Power Block, Wind Power Special Lifting Cable Block with Shackle

Technique advantages:

1. The shackle and lifting axis are forged by alloy steel and heat treated.

2. The rolling wheel is gorged by steel.

3. The side board with sides can prevent clamping rope.

4. Nylon composite bush and DS-JDB solid oily self-lubricating copper bush are available.

5. It can be opened, and escaped by rope when the lifting rod lifts the pulley.

6. Oil nipple for operating easily.

7. The rated fatigue strength is superior to the equal standard.

Industry solution:

The new energy-wind power generation has been greatly carried out at home and abroad. Wind power is an environmental and clean energy.Meanwhile, the hoisting solution of wind power designed by the Dawson block research center has been successively applied in the installation works at home and abroad.

Basic Parameters of Wind Power Special Lifting Cable Block

| Item No. | WLL (Kn) | Applicable Steel Cable(mm) | Specification(mm) |

| H | D | D1 |

| DS-WPB3119-25T | 245 | 31-36 | 1300 | 500 | 540 |

| DS-WPB3120-35T | 343 | 34-39 | 1380 | 510 | 545 |

| DS-WPB3122-45T | 441 | 39-40 | 1520 | 560 | 690 |

| DS-WPB3124-55T | 539 | 40-48 | 1600 | 600 | 630 |

| DS-WPB3126-70T | 686 | 48-52 | 1750 | 650 | 680

|

| Item No. | Load of sling | Single-lifting lug load | Wide-body shackle | WPB | Lug bolt and hole distance |

| DS-WPB3115-35T | 50T | 15T | 35T | 35T | Made based on tower flange |

| DS-WPB3118-40T | 60T | 18T | 35T | 40T | Made based on tower flange |

| DS-WPB3118-45T | 65T | 20T | 35T | 45T | Made based on tower flange |

| DS-WPB3118-50T | 70T | 30T | 50T | 50T | Made based on tower flange |

| DS-WPB3118-55T | 80T | 35T | 50T | 55T | Made based on tower flange |

| DS-WPB3118-70T | 100T | 40T | 60T | 70T | Made based on tower flange

|

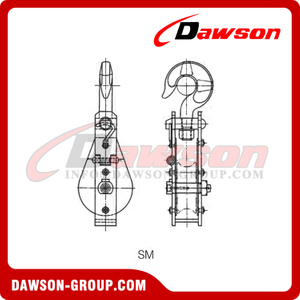

Marine Block, Marine Steel Cable Block, Boat Steel Cable Block, Single Sheave Marine Block, Multi-Seave Marine Block, Double Hook Marine Block, Tied Groove Opening Block

Technology advantages:

1. Reinforced plate and special sealing device:resistance to corrosion.Both sides of the middle shaft are installed with water-proofing sealing devices.

2. Alloy material:the ring and hook are made of high-quality 20Mn or 35CrMo.

3. Equipped with DS-JDB embedded solid oily copper alloy sliding bearing: greatly improve the impact force.

4. The bundled chain ring and clamp ring are forged by alloy steel, with bronze bushing.

5. The steel cable tortoise shell is made of steel casting. The pulley rotates flexibly with long cylindrical roller bearing.Thus,

Industry solution

As there are requirements for the resistant to corrosion and impact force, Dawson Block Design Center has innovated and adopted reinforced plates and special sealing device. Thus, impact force has been greatly strengthened and hoisting and pulling and pushing safety is greatly improved. A,B,C,D and ZHC marine blocks are available. The solution for hoisting and underwater hauling is provided for dozens of shipbuilding enterprises, including Qingdao Ship Yard, Shanghai Ship Yard and Yantai Raffles and so on.

Basic parameters of Type A marine block

| Model | WLL(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| D | B | L | H |

| DS-A1C(Y.Z) Type | 10 | 13.5 | 175 | 210 | 88 | 430 |

| 20 | 15.5 | 200 | 250 | 102 | 566 |

| 32 | 19.5 | 250 | 310 | 120 | 680 |

| 40 | 21.5 | 285 | 350 | 134 | 740 |

| 50 | 26.0 | 335 | 410 | 151 | 872 |

| 63 | 28.0 | 365 | 455 | 172 | 965 |

| 80 | 32.5 | 420 | 520 | 194 | 1070 |

| 100 | 34.5 | 450 | 550 | 208 | 1176 |

| DS-A1CS(Y.Z) Type | 125 | 32.5 | 420 | 520 | 194 | 1274 |

| 160 | 34.5 | 450 | 550 | 208 | 1404 |

| DS-A2C(Y.Z) Type | 80 | 15.5 | 200 | 250 | 175 | 640 |

| 125 | 19.5 | 250 | 310 | 205 | 786 |

| 160 | 21.5 | 285 | 350 | 226 | 874 |

| 200 | 26.0 | 335 | 410 | 260 | 1015 |

| DS-A2CS(Y.Z) Type | 100 | 15.5 | 200 | 250 | 175 | 730 |

| 160 | 19.5 | 250 | 310 | 205 | 900 |

| 200 | 21.5 | 285 | 350 | 226 | 995 |

| 250 | 26.0 | 335 | 410 | 260 | 1160

|

Basic parameters of Type B marine block

| Model | WLL(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| D | B | L | H |

| DS-BG1C(1Y) Type | 32 | 19.5 | 250 | 310 | 134 | 675 |

| 50 | 26.0 | 335 | 410 | 146 | 866 |

| 80 | 32.5 | 420 | 510 | 170 | 1076 |

| 100 | 34.5 | 450 | 550 | 186 | 186 |

| DS-BG1CS(1Y) Type | 50 | 19.5 | 250 | 310 | 134 | 712 |

| 80 | 26.0 | 335 | 410 | 146 | 926 |

| 120 | 32.5 | 420 | 510 | 170 | 1130 |

| 160 | 34.5 | 450 | 550 | 186 | 1150 |

| DS-BZ2C(2Y) Type | 125 | 19.5 | 250 | 310 | 228 | 756 |

| 200 | 26.0 | 335 | 410 | 250 | 960 |

| DS-BZ2CS(2Y) Type | 160 | 19.5 | 250 | 310 | 228 | 790 |

| 250 | 26.0 | 335 | 410 | 250 | 995

|

Basic parameters of Type C marine steel cable block

| Model | WLL(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| D | B | L | H |

| DS-C1C(G) Type | 10 | 13.0 | 175 | 210 | 88 | 430 |

| 20 | 15.5 | 200 | 250 | 102 | 566 |

| 32 | 19.5 | 250 | 310 | 120 | 680 |

| 40 | 21.5 | 285 | 350 | 134 | 740 |

| 50 | 26.0 | 335 | 410 | 151 | 872 |

| 16 | 13.5 | 175 | 210 | 88 | 516 |

| 32 | 15.5 | 200 | 250 | 102 | 658 |

| 50 | 19.5 | 250 | 310 | 120 | 780 |

| DS-C1CS(GS) Type | 63 | 21.5 | 285 | 350 | 134 | 887 |

| 80 | 26.0 | 335 | 410 | 151 | 1042 |

| DS-C2C(G) Type | 40 | 13.5 | 175 | 210 | 105 | 568 |

| 80 | 15.5 | 200 | 250 | 130 | 685 |

| 125 | 19.5 | 250 | 310 | 150 | 851 |

| 160 | 21.5 | 285 | 350 | 166 | 960 |

| 200 | 26.0 | 335 | 410 | 188 | 1072 |

| DS-C2CS(GS) Type | 50 | 13.5 | 175 | 210 | 105 | 630 |

| 100 | 15.5 | 200 | 250 | 130 | 777 |

| 160 | 19.5 | 250 | 310 | 150 | 968 |

| 200 | 21.5 | 285 | 350 | 166 | 1081 |

| 250 | 26.0 | 335 | 410 | 188 | 1218

|

Basic parameters of Type D boat steel cable block

| Model | WLL(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| D | B | L | H |

| DS-D3Type | 125 | 15.5 | 200 | 250 | 188 | 546 |

| 200 | 19.5 | 250 | 310 | 208 | 673 |

| 250 | 21.5 | 285 | 350 | 238 | 744 |

| 300 | 26.0 | 335 | 410 | 264 | 866 |

| 400 | 28.0 | 365 | 455 | 290 | 970 |

| 500 | 32.5 | 420 | 520 | 308 | 1095 |

| DS-D3SType | 145 | 15.5 | 200 | 250 | 188 | 643.5 |

| 232 | 19.5 | 250 | 310 | 208 | 792 |

| 290 | 21.5 | 285 | 350 | 238 | 879 |

| 350 | 26.0 | 335 | 410 | 264 | 1018 |

| 463 | 28.0 | 365 | 455 | 290 | 1139 |

| 580 | 32.5 | 420 | 520 | 308 | 1277 |

| DS-D4Type | 250 | 19.5 | 250 | 310 | 264 | 663 |

| 320 | 21.5 | 285 | 350 | 302 | 750 |

| 400 | 26.0 | 335 | 410 | 335 | 900 |

| 500 | 28.0 | 365 | 455 | 368 | 1005 |

| 630 | 32.5 | 400 | 520 | 392 | 1131 |

| 800 | 34.5 | 450 | 550 | 425 | 1248 |

| DS-D4SType | 282 | 19.5 | 250 | 310 | 264 | 782 |

| 360 | 21.5 | 285 | 350 | 320 | 885 |

| 450 | 26.0 | 335 | 410 | 335 | 1052 |

| 563 | 28.0 | 365 | 455 | 368 | 1174 |

| 710 | 32.5 | 420 | 520 | 392 | 1313 |

| 900 | 34.5 | 450 | 550 | 425 | 1448

|

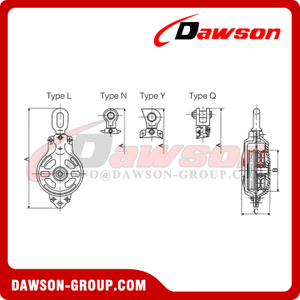

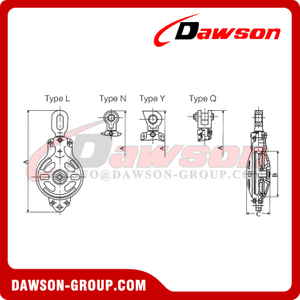

Basic parameters of Type ZHC single-sheave marine block

| Model | Rated load(KN) | Applicable steel cable diameter(mm) | A(mm) | B(mm) | C(mm) | D(mm) |

| L | Q | N |

| DS-ZHC3.2-1L(Q.N) | 31.36 | 15-17 | 590 | 565 | 536 | 274 | 122 | 260 |

| DS-ZHC5-1L(Q.N) | 49 | 20-22 | 733 | 711 | 675 | 330 | 160 | 300 |

| DS-ZHC8-1L(Q.N) | 78.4 | 22-24 | 885 | 858 | 800 | 385 | 165 | 355 |

| DS-ZHC10-1L(Q.N) | 98 | 24-26 | 1000 | 970 | 930 | 440 | 170 | 410 |

| DS-ZHC16-1L(Q.N) | 156.8 | 26-28 | 1142 | 1108 | 1061 | 490 | 210 | 460 |

| DS-ZHC20-1L(Q.N) | 196 | 28-30 | 1145 | 1110 | 1070 | 490 | 214 | 460

|

Basic parameters of Type ZHC multi-sheave marine block

| Model | Rated load(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| A | B | C | D |

| DS-125-ZHC550×7Q | 1225 | 28-30 |

| 550 | 790 | 590 |

| DS-125-ZHC550×7QS | 1525 |

| DS-125-ZHC600×7Q | 1225 | 28-30 |

| 600 | 860 | 640 |

| DS-125-ZHC600×7QS | 1560 |

| DS-140-ZHC550×7Q | 1372 | 28-30 |

| 550 | 810 | 590 |

| DS-140-ZHC550×7QS | 1563 |

| DS-100-ZHC550×7Q | 980 | 26-28 |

| 550 | 700 | 590 |

| DS-100-ZHC550×7QS | 1448

|

SG Type multi-sheave double-hook marine block

| Model | Rated load(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| A | B | C | D | E |

| DS-32-ZHC460×4SG | 313.6 | 26-28 | 1895 | 625 | 150 | 460 | 490 |

| DS-40-ZHC500×4SG | 392.0 | 26-28 | 2125 | 695 | 180 | 500 | 540 |

| DS-32-ZHC550×4SG | 313.6 | 28-30 | 2015 | 625 | 150 | 550 | 590 |

| DS-40-ZHC550×4SG | 392.0 | 28-30 | 2175 | 695 | 180 | 550 | 590 |

| DS-63-ZHC550×4SG | 617.4 | 28-30 | 1683 | 730 | 200 | 550 | 590

|

Tied groove opening block

| Rared load(KN) | Applicable steel cable diameter(mm) | Basic parameters(mm) |

| A | B | C | D | E | F | G |

| 30 | 18-22 | 84 | 125 | 65 | 96 | 40 | 413 | 140 |

| 50 | 22-26 | 88 | 150 | 80 | 102 | 40 | 437 | 162

|

Mining Block, Special Lifting Tackle

Mining Block, Special Lifting Tackle

Technology advantages:

1. With the wire rope locating and anti-disengaging device, the wire rope will not fall from the groove and the guard plate and pulley will not be damaged.

2. Pressure bearing locating device:applicable to operation under all angles, the pulley edges and guard plates are not rubbed with each other.

3. Reinforced plate and thickened plate are adopted to prevent deformation.

4. Bolted retaining plate:make the tackle become stronger.

Industry Solution

Mining block is a special lifting tackle that is self-researched by our company for the coal mine industry, which has filled in the gap of Chinese tackle industry. As the operation environment of inside mine is severe and complex, horizontal drawing, non-linear pulling and pulling from different angles are required.Different from the traditional vertical hoisting, horizontal drawing or non-linear pulling is required for coal mine tackle. Therefore, Dawson Block Design Team has closely communicated with the clients by operation survey and has designed the mine tackle, which has filled in the industry gap.

| Item | Model | WLL(KN) | Wire rope diameter(mm) | D(mm) | H(mm) | B(mm) | L(mm) |

| Mine tackle | DS-HY(HQ)G(D)1-10 | 100 | 23-24.5 | 280 | 750 | 316 | 110 |

| DS-HY(HQ)G(D)1-16 | 160 | 28-31 | 345 | 905 | 365 | 145 |

| DS-HY(HQ)G(D)1-20 | 200 | 31-35 | 390 | 1065 | 410 | 152 |

| DS-HY(HQ)G(D)1-32 | 320 | 34-38 | 490 | 1280 | 520 | 209

|

Electricity Block, Electric Block with Roller Bearing and Steel Sheave

Line tackle with small diameter

| Model | Applicable wire(LGJ) | Rated load(KN) | Outer diameter(mm) | Block width(mm) | Weight(Kg) |

| DS-EPB-∅120 | 25-70 | 5 | 120 | 35 | 1.5 |

| DS-EPB-∅160 | 95-120 | 10 | 160 | 40 | 2.5 |

| DS-EPB-∅200 | 150-240 | 15 | 200 | 40 | 3.6 |

| DS-EPB-∅200 | 150-240 | 15 | 200 | 60 | 4.5 |

| DS-EPB-∅270 | 300-400 | 20 | 270 | 60 | 5.6 |

| DS-EPB-∅320 | 300-400 | 20 | 320 | 60 | 6.7 |

| DS-EPB-∅408 | 400-500 | 20 | 408 | 80 | 13.0

|

Application:the product is used to place the wire on the straight line pole. The pliers-connected pipe, wire rope connector and rotary connector pass through the groove.

Explanation: 1. There are hook-type tackle, hanging-panel-type, ring-type tackles. Thus, please specify the type. The special specification will be customized.

High- speed angle tackle

| Model | Rated load(KN) | Pulley outer diameter(mm) | Pulley width(mm) | Weight(Kg) | Remarks |

| DS-EPB-5 | 50 | ∅308 | 75 | 22 | Steel pulley |

| DS-EPB-16 | 160 | ∅600 | 92 | 150 | Steel pulley |

| DS-EPB-30 | 300 | ∅916 | 110 | 200 | Steel pulley

|

Application: to pull the wire rope angle during paying off. It can pass through the wire rope is 80m/min.

Electric block with roller bearing and steel sheave

| Model | Number of pulleys | Rated load(KN) | Applicable wire rope(mm) | Weight(Kg) |

| DS-EPB1×1 | 1 | 10 | ∅7.7 | 3.0 |

| DS-EPB1×2 | 2 | 10 | ∅5.7 | 3.0 |

| DS-EPB1×3 | 3 | 10 | ∅5.7 | 4.3 |

| DS-EPB2×1 | 1 | 20 | ∅11.0 | 4.7 |

| DS-EPB2×2 | 2 | 20 | ∅7.7 | 5.3 |

| DS-EPB2×3 | 3 | 20 | ∅7.7 | 7.2 |

| DS-EPB3×1 | 1 | 30 | ∅12.5 | 6.5 |

| DS-EPB3×2 | 2 | 30 | ∅11.0 | 7.8 |

| DS-EPB3×3 | 3 | 30 | ∅7.7 | 10.5 |

| DS-EPB5×1 | 1 | 50 | ∅15.5 | 9.0 |

| DS-EPB5×2 | 2 | 50 | ∅12.5 | 10.8 |

| DS-EPB5×3 | 3 | 50 | ∅11.0 | 13.8 |

| DS-EPB8×1 | 1 | 80 | ∅18.5 | 14.4 |

| DS-EPB8×2 | 2 | 80 | ∅15.5 | 19.0 |

| DS-EPB8×3 | 3 | 80 | ∅12.5 | 19.8 |

| DS-EPB10×1 | 1 | 100 | ∅20.0 | 21.0 |

| DS-EPB10×2 | 2 | 100 | ∅15.5 | 24.0 |

| DS-EPB10×3 | 3 | 100 | ∅15.5 | 24.8

|

Application: applicable to assembling the pole and tower, wire stringing, hoisting equipment and other overweight operation during electric line construction.

Remarks: specify the required opening, closing, hook type and ring type during ordering.

Oilfield Block, Oilfield Drilling Block, Oilfield Pipe Block, Traveling Block, Lifting Tackle

| Model | Working load (TON) | Sheave diameter(mm) | Number of rounds | Applicable wire rope(mm) | Weight(KG) |

| DS2-250 | 250 | 750 | 4 | 28.5 | 2500 |

| DS2-350 | 350 | 1050 | 5 | 31.7 | 3200 |

| DS2-500 | 500 | 1350 | 5 | 35 | 7200 |

| DS2-750 | 750 | 1350 | 6 | 38 | 9000

|

It is forbidden to use the heavy weights next to the station.

Technique Advantages:

1. The pulley is hot rolled with Q345B steel plate and the wheel groove is quenched with flame.

2. The slot matched with the wire rope effectively extends the service life of both.

3. The long cylindrical roller bearings are assembled in the hub to design their respective lubricating oil ducts.

4. The lifting device is treated with 35 CrMO alloy steel, which ensures the payload safety.

5. The crane assembly thrust bearings, more flexible and convenient when working.

6. By increasing the weight to increase the speed, eliminate the vibration, more stable operation.

7. The slide surface is painted, and also anti rust treatment.

Oilfield Pipe Block

| Model | Working load(TON) | Sheave diameter(mm) | Applicable wire rope(mm) | Weight(KG) |

| DS3-1-75 | 75 | 500 | 22 | 850 |

| DS3-2-75 | 75 | 500 | 22 | 880 |

| DS3-1-100 | 100 | 600 | 25 | 1250 |

| DS3-2-100 | 100 | 600 | 25 | 1300 |

| DS3-1-140 | 140 | 760 | 28 | 1900 |

| DS3-2-140 | 140 | 760 | 28 | 2200

|

| Model | Working load(TON) | Sheave diameter(mm) | Applicable wire rope(mm) | Weight(KG) |

| DS4-50 | 50 | 430 | 22 | 480 |

| DS4-75 | 75 | 500 | 25 | 720 |

| DS4-100 | 100 | 610 | 25 | 990 |

| DS4-150 | 150 | 760 | 28.5 | 1200

|

Technique Advantages:

1. The pulley is hot rolled with Q345B steel plate and the wheel groove is quenched with flame.

2. The slot matched with the wire rope effectively extends the service life of both.

3. The long cylindrical roller bearings are assembled in the hub to design their respective lubricating oil ducts.

4. The lifting device is treated with 35 CrMO alloy steel, which ensures the payload safety.

5. The crane assembly thrust bearings, more flexible and convenient when working.

6. By increasing the weight to increase the speed, eliminate the vibration, more stable operation.

7. The slide surface is painted, and also anti rust treatment.

Custom Block, Shackle Type Marine Block, Lifting Tackle

Custom Block

| Lifting load(TON) | Applicable wire rope (mm) | Pulley diameter(mm) | Weight(KG) |

| 10 | 15-17 | 254 | 162 |

| 20 | 25-26 | 380 | 216 |

| 30 | 28-29 | 418 | 279 |

| 40 | 32-35 | 645 | 380

|

Technique Advantages:

1. The guard plates on both sides are equipped with balancing weight to make the massive structure firmer.

2. The pulley is made of Q345B plate and the pulley groove bottom is quenched.

3. The hook or shackle is made of high-alloy steel and quenched-tempered heat treatment.

4. The hub is equipped with DS-JDB oily copper alloy or long cylindrical roller bearing.

5. The hook is equipped with safety closed pin.

Shackle-type marine block

| Work load(TON) | Pulley diameter(mm) | Wire rope diameter(mm) | Weight(KG) |

| 30 | 24-26 | 400 | 120 |

| 30 | 35-38 | 500 | 125 |

| 60 | 36-40 | 600 | 220 |

| 60 | 50-52 | 620 | 225

|

Technology Advantages:

1. The key technical indicators meet EU standard:13157

2. High-alloy steel forging and heat treatment process.

3. Pulley is made of hot rolled steel pulley and MC nylon pulley and is applicable to -20°operation.

4. MC nylon pulley can lengthen the service life of wire rope for more than 5 times.

5. The rolled steel pulley is equipped with DS-JDB solid oily self-lubricating copper bushing.

6. After anti-septic treatment, the tackle surface is sprayed with coating.

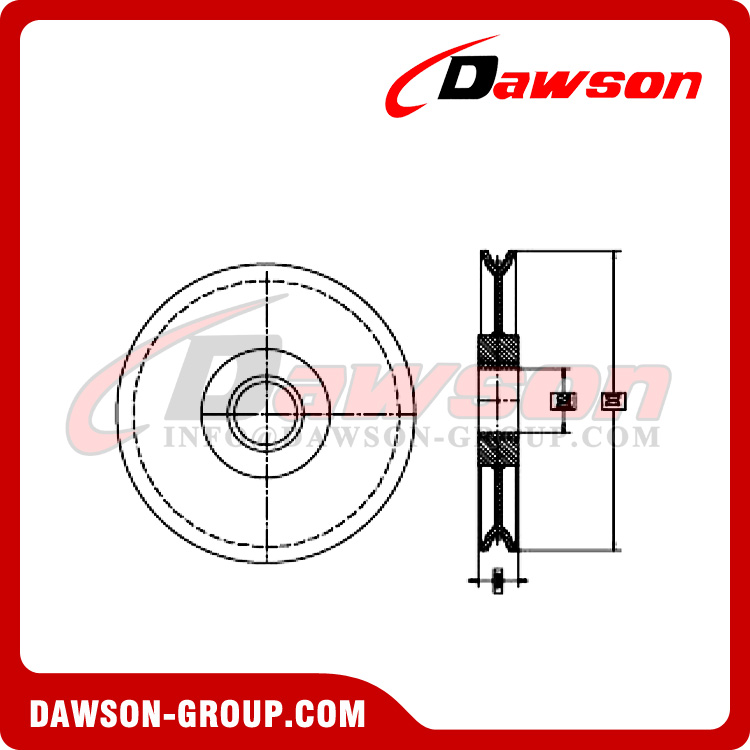

Hot Rolled Steel Sheave, Hot Rolled Steel Pulley Block

Basic parameter of hot rolled steel pulley

| Item | D(mm) | B(mm) | Extreme tolerances | Applicable wire rope diameter(mm) | DS-JDB embedded solid oily copper alloy shaft bush Φ(mm) | Long cylindrical roller bearing model (D2) |

| Hot rolled steel Sheave | 300-390 | 50-60 | +2.0 | 14-15.5 | 50-60 | 42212 |

| 390-435 | 60-65 | +2.5 | 15.5-17 | 60-70 | 42213 |

| 435-490 | 65-70 | +3.0 | 17-20 | 70-75 | 42214 |

| 490-560 | 75-80 | +3.5 | 20-24.5 | 75-80 | 42215 |

| 560-760 | 80-90 | +4.0 | 24.5-30 | 80-85 | 42216 |

| 760-820 | 90-100 | +4.5 | 30-37 | 85-90 | 42217 |

| 820-1000 | 100-120 | +5.0 | 37-52 | 90-100 | 42218 |

| 1000-1200 | 105-130 | +5.5 | 52-60 | 100-110 | Customized according to customer requirements |

| 1200-1400 | 110-140 | +6.0 | 60-65 | 110-120 | Customized according to customer requirements |

| 1400-1600 | 120-150 | +6.5 | 65-70 | 120-130 | Customized according to customer requirements

|

Technology advantages:

Compared with the general cast iron sheave, the hot rolled steel sheave could not be broken. It replaces the traditional cast iron and cast steel sheaves, which has filled in the domestic gap. The hot rolled steel sheave is available from ∅150-1800MM, and the international advanced technology is adopted. Its advantages are:

1. It is highly resistant to tension and impact force.

2. It is resistant to wear and has large bearing load. The service life is more than 5 times of the iron pulley.

3. The pulley groove is quenched, the friction coefficient with the wire rope is small, so the service life of the wire rope is lengthened.

Industry solution

Our technology research center has researched the key part of tackle”pulley” in order to solve the disadvantages of traditional cast iron and cast steel pulley. Through repeated test, large multi-pulley singing tackle with”single-plate” hot rolled steel sheave” has been successively produced. The tackle has been applied to large projects, such as the Three Gorges, Qingdao Port, Raffles drilling platform borehole.

Quench hardening technology:

With the technology, the sheave groove is quenched and hardened. The maximum hardness is provided on the touch surface of the wire rope to resist the resistance. 140° touch area is generated with the wire rope. The steel plate surface is very applicable to quenched hardening to reduce the tolerance and fatigue and wear.

Welcome to buy the newest and competitive price DAWSON DAWSON Heavy Duty Snatch Block, Lifting Pulley Blocks, Wire Rope Pulley from our factory. We're one of the leading China manufacturers and suppliers, offering you the wholesale service and the OEM service at a discount. With CE certification, our products made in China in stock are high in quality and low in price. Please be free to get the free sample from us.

For further information, please contact us. Email:info@dawson-group.com

Hot Tags: heavy duty snatch block,heavy duty pulley blocks,lifting pulley block, wire rope pulley blocks,general block,nylon block,bronze bearing block,hot-rolled steel sheave block,wire rope pulley,buy discount wind power block,marine block in stock,competitive price electricity block,hot sale oilfield block

Products Show:

Other related products:

DAWSON Quality Management System:

DAWSON Forging:

Heavy Duty Snatch Block Catalogue Download:

Application of Snatch Block:

Factory & Package Show:

English

English