- Dawson Group Ltd. - China Manufacturer, Supplier, Factory

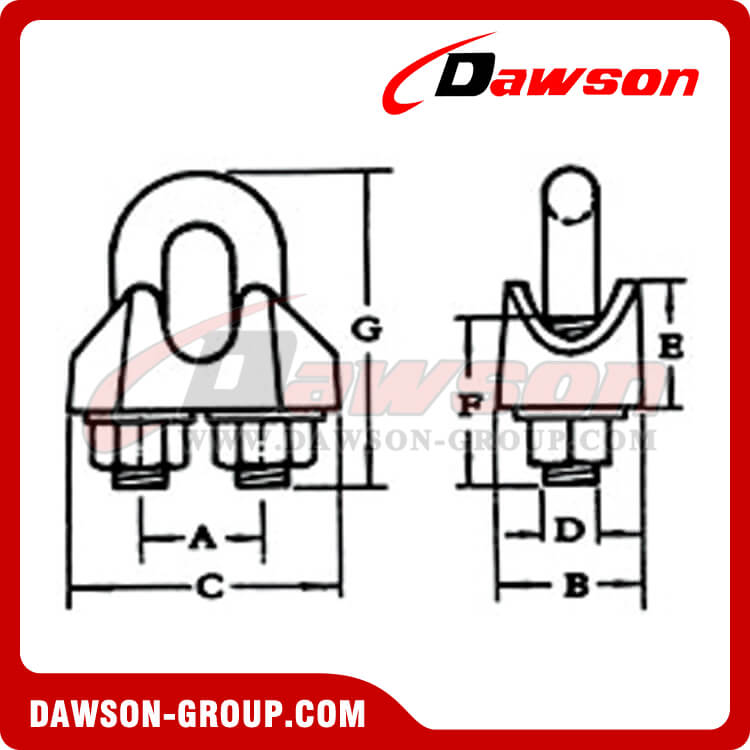

Galv. Malleable Wire Rope Clip Din 1142

Material: Body with malleable cast, Heavy duty Type, U-BOLT with mild steel.

Finished: Galv.

Packing: Gunny Bags and then on pallets.

| ITEM NO | SIZE

mm | A

mm | B

mm | C

mm | D

mm | E

mm | F

mm | G

mm |

| DS-GMWC4205 | 5 | 12 | 13 | 25 | 5 | 13 | 14 | 25 |

| DS-GMWC4206 | 6.5 | 14 | 16 | 30 | 6 | 14 | 17 | 32 |

| DS-GMWC4208 | 8 | 18 | 20 | 39 | 8 | 18 | 20 | 41 |

| DS-GMWC4210 | 10 | 20 | 20 | 40 | 8 | 21 | 24 | 46 |

| DS-GMWC4212 | 12 | 24 | 25 | 50 | 10 | 24 | 28 | 56 |

| DS-GMWC4213 | 13 | 29 | 28 | 55 | 12 | 29 | 29 | 64 |

| DS-GMWC4214 | 14 | 28 | 30 | 59 | 12 | 28 | 31 | 66 |

| DS-GMWC4216 | 16 | 34 | 32 | 64 | 14 | 35 | 35 | 76 |

| DS-GMWC4219 | 19 | 37 | 33 | 68 | 14 | 40 | 36 | 83 |

| DS-GMWC4222 | 22 | 41 | 34 | 74 | 16 | 44 | 40 | 96 |

| DS-GMWC4226 | 26 | 46 | 38 | 84 | 20 | 51 | 50 | 111 |

| DS-GMWC4230 | 30 | 54 | 41 | 95 | 20 | 59 | 55 | 127 |

| DS-GMWC4234 | 34 | 60 | 45 | 105 | 22 | 67 | 60 | 141 |

| DS-GMWC4240 | 40 | 68 | 49 | 117 | 24 | 77 | 65 | 159

|

Application

Wire rope clips are used on wire rope eye-loop connections or complete loops, end-to-end connections where socketing or splicing is not feasible or when a temporary joint is required.

Range

Dawson offers a wide range of wire rope clips in specifically standardized models such as EN 13411-5 and DIN wire rope clips. also offers a wide range of other wire rope clips

Design

Dawson wire rope clips are drop forged and have a bridge with grooves to tighten the wire rope properly in the clip; the DIN wire rope clips have a malleable base, without grooves.

Wire rope clips are generally marked with:

• manufacturer’s symbol - e.g. DAWSON

• wire rope diameter in mm or inches - e.g. 13 or 1/2”

• traceability code - e.g. DS22

The efficiency of a wire rope termination made with wire rope clips depends on the correct placement of the clips on the rope and on correct fitting and tightening of the clips. With inadequately tightened nuts or with an insufficient number of wire rope clips the rope end may slide through the clips during use.

The fitting of the clips on the ropes may be affected by various circumstances, such as:

• the nut may be tight on the thread, yet not tight against the bridge;

• contamination of the thread by dirt, oil or corrosion products, which may prevent correct tightening of the nut.

Forged wire rope clips provide greater bearing surface and more consistent strength than malleable cast iron clips.

Wire rope clips should not be used in following applications:

• hoist ropes in mines;

• rope drives for cranes in steel works and rolling mills;

• permanent fastening of ropes in other rope drives;

• rope terminations for load suspension devices in the operation of lifting appliances, except in the case of lifting tackles where these are produced for a special application and used only once.

Wire rope clips must be regularly inspected in accordance with the safety standards given in the country of use. This is required because the products in use may be affected by wear, misuse, overloading etc. Which may lead to deformation and alteration of the material structure. Inspection should take place at least every six months and more frequently when the products are used in severe operating conditions.

Products Detail:

Products Show:

Hot Tags: malleable wire rope clip, forged steel wire rope clip, DIN 1142 Wire Rope Grips, galvanized wire rope clip, din 1142 wire rope grip, wire rope clip, steel wire rope clip, mild steel wire rope clip, electric galvanized wire rope clip, hot dipped galvanized wire rope clip, wire rope clip China supplier, wire rope clip China manufacturer, wire rope clip China exporter, high quality wire rope clip  English

English