Instructions:

Optimized designing, DIN/FEM standard, smaller wheel load, space saving.

Double welding box girder, DIN/FEM standard deflection.

Shot-blasting Sa2.5 for complete girder after welding, stress release.

Trolley rail is high strength flat steel bar(hot rolled, 16Mn)

Epoxy zinc rich high quality paiting,2 ×2with 140 µm

10.9 class High tension bolts mouting between girder and legs, life time safety connection

Compacted gear motor driving, steeples control, harden gear, safety disck brake.

High protection class IP55, F class,40% ED

First class lifting units, maintenance free

Gear motor locker rope to protect drop

Flexible solution for all lifting needs

Excellent driving properties ,steeples control, smoothly moving

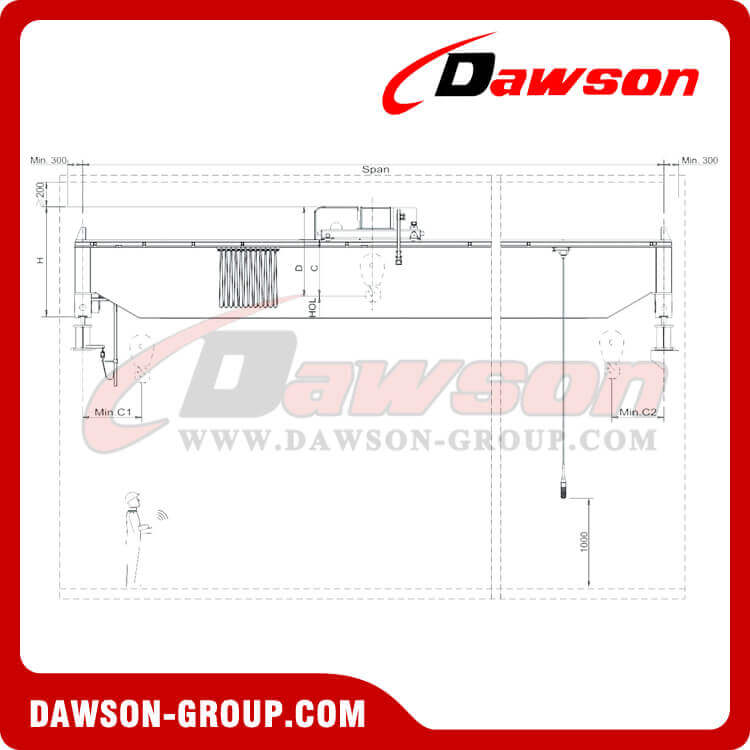

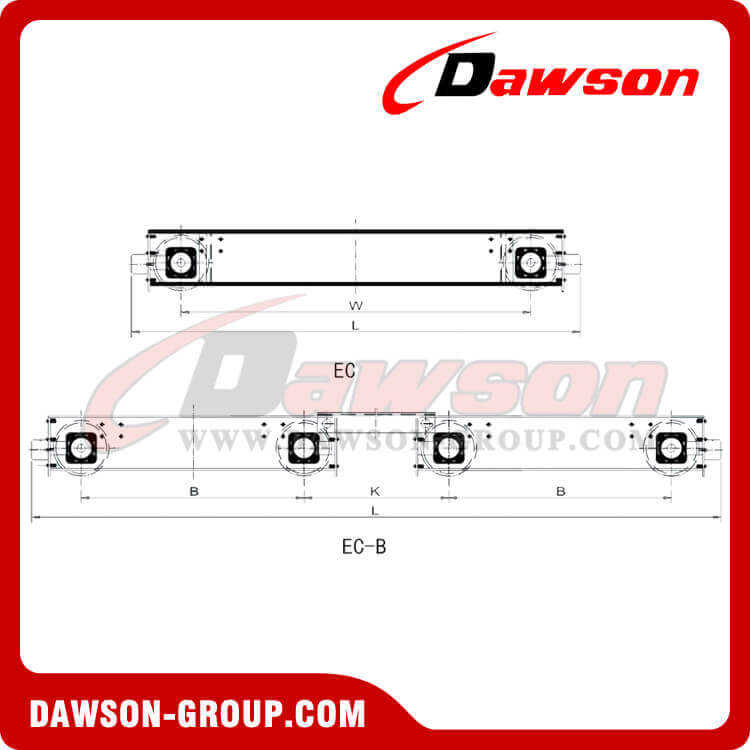

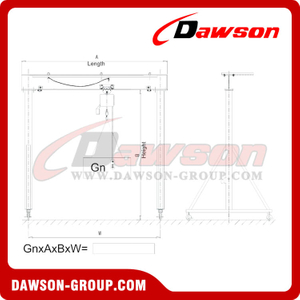

| SWL | Span | Lifting height | FEM | Lifting speed | Main size | Press Max | Trolley | Crane weight | Crane power | Rail |

| W | L | B | K | C | D | C1 | C2 | H |

| t | m | m | M/min | mm | mm | mm | mm | mm | mm | mm | mm | mm | kN | kg | kg | kW | kg |

| 5 | 13.5 | 9 | A5

2M | 5/0.8 | 2200 | 2556 | / | / | 350 | 780 | 850 | 1100 | 979 | 41.4 | 670.0 | 4750 | 7.3 | 22 |

| 16.5 | 2700 | 3116 | / | / | 979 | 46.5 | 6720 | 7.3 | 22 |

| 19.5 | 3100 | 3550 | / | / | 979 | 51.9 | 8840 | 7.6 | 22 |

| 22.5 | 3800 | 4250 | / | / | 979 | 56.4 | 10670 | 7.6 | 22 |

| 25.5 | 3800 | 4250 | / | / | 979 | 61.4 | 12520 | 7.6 | 22 |

| 28.5 | 4500 | 5010 | / | / | 1229 | 67.9 | 15220 | 8 | 38 |

| 10 | 13.5 | 9 | A5

2M | 5/0.8 | 2700 | 3176 | / | / | 360 | 900 | 850 | 1100 | 1640 | 69.6 | 920.0 | 6070 | 11.4 | 22 |

| 16.5 | 2700 | 3210 | / | / | 1640 | 74.4 | 7600 | 11.8 | 22 |

| 19.5 | 3100 | 3610 | / | / | 1220 | 78.9 | 9400 | 12.5 | 22 |

| 22.5 | 3800 | 4384 | / | / | 1220 | 84.3 | 11670 | 12.5 | 22 |

| 25.5 | 3800 | 4310 | / | / | 1215 | 89.9 | 13740 | 12.5 | 38 |

| 28.5 | 4435 | 4925 | 1400 | 1635 | 1292 | 50.7 | 16310 | 13.3 | 38 |

| 31.5 | 4922 | 5472 | 1400 | 2122 | 1792 | 59.1 | 20840 | 13.3 | 43 |

| 15 | 13.5 | 9 | A5

2M | 4/0.66 | 3800 | 4384 | / | / | 480 | 1120 | 1000 | 1100 | 1625 | 100.0 | 1380.0 | 7320 | 19.3 | 22 |

| 16.5 | 3800 | 4384 | / | / | 1625 | 105.9 | 8960 | 19.3 | 22 |

| 19.5 | 3800 | 4384 | / | / | 1625 | 111.1 | 10750 | 19.3 | 22 |

| 22.5 | 4527 | 4527 | 1200 | 2127 | 1375 | 59.8 | 12420 | 20.1 | 22 |

| 25.5 | 4549 | 4549 | 1200 | 2149 | 1375 | 63.0 | 14710 | 20.1 | 38 |

| 28.5 | 4573 | 4573 | 1200 | 2173 | 1375 | 68.1 | 18570 | 20.1 | 38 |

| 31.5 | 5245 | 5245 | 1800 | 1645 | 1692 | 74.0 | 22640 | 20.1 | 43 |

| 20 | 13.5 | 9 | A5

2M | 3.4/0.53 | 3800 | 4384 | / | / | 480 | 112 | 1460 | 1330 | 1625 | 128.2 | 2200.0 | 9190 | 19.3 | 43 |

| 16.5 | 3800 | 4384 | / | / | 1625 | 134.1 | 10840 | 19.3 | 43 |

| 19.5 | 3800 | 4384 | / | / | 1625 | 139.5 | 12490 | 19.3 | 43 |

| 22.5 | 3793 | 4243 | 1200 | 1393 | 1525 | 72.8 | 13090 | 20.1 | 43 |

| 25.5 | 3815 | 4265 | 1200 | 1415 | 1525 | 76.3 | 15890 | 20.1 | 43 |

| 28.5 | 4438 | 4988 | 1800 | 838 | 1525 | 84.1 | 21040 | 20.1 | 43 |

| 31.5 | 5000 | 5550 | 1600 | 1800 | 1825 | 87.6 | 23500 | 20.1 | 70 |

| 25 | 13.5 | 9 | A5

2M | 3.3/0.8 | 2700 | 3284 | / | / | 620 | 1410 | 1460 | 1330 | 1775 | 147.8 | 2600.0 | 7790 | 25.2 | 43 |

| 16.5 | 3100 | 3874 | / | / | 1775 | 156.0 | 10560 | 25.2 | 43 |

| 19.5 | 3100 | 3874 | / | / | 1775 | 163.9 | 13060 | 25.2 | 43 |

| 22.5 | 3770 | 4220 | 1200 | 1370 | 1575 | 74.5 | 14220 | 26.6 | 43 |

| 25.5 | 3988 | 4538 | 1400 | 1188 | 1575 | 78.9 | 17380 | 26.6 | 43 |

| 28.5 | 4510 | 5060 | 1600 | 1310 | 1575 | 98.6 | 22310 | 26.6 | 43 |

| 31.5 | 5167 | 5827 | 1800 | 1567 | 2075 | 113.0 | 25270 | 26.6 | 70 |

| 32 | 13.5 | 9 | A5

2M | 3.3/0.8 | 3477 | 3987 | 1400 | 677 | 620 | 1410 | 1480 | 1520 | 2075 | 95.1 | 2900.0 | 8700 | 26.6 | 43 |

| 16.5 | 3492 | 4002 | 1400 | 692 | 2075 | 98.8 | 10670 | 26.6 | 43 |

| 19.5 | 3524 | 4034 | 1400 | 724 | 2075 | 103.3 | 13640 | 26.6 | 43 |

| 22.5 | 3543 | 4093 | 1400 | 743 | 2075 | 107.7 | 16570 | 26.6 | 43 |

| 25.5 | 3959 | 4509 | 1400 | 1159 | 2075 | 111.5 | 19290 | 26.6 | 43 |

| 28.5 | 4533 | 5193 | 1600 | 1333 | 2175 | 121.6 | 27150 | 26.6 | 70 |

| 31.5 | 5180 | 5840 | 1800 | 1580 | 2175 | 124.0 | 28500 | 26.6 | 70 |

| 40 | 13.5 | 9 | A5

2M | 0-4.1 | 3800 | 4574 | / | / | 980 | 1880 | 1480 | 1520 | 2180 | 231.2 | 3500.0 | 11680 | 45.4 | 43 |

| 16.5 | 3800 | 4574 | / | / | 2180 | 231.2 | 14220 | 45.4 | 43 |

| 19.5 | 3800 | 4614 | / | / | 2180 | 250.1 | 17210 | 45.4 | 43 |

| 22.5 | 3569 | 4193 | 1400 | 769 | 2180 | 136.5 | 19550 | 47 | 43 |

| 25.5 | 3600 | 4280 | 1300 | 1000 | 2180 | 138.0 | 25790 | 47 | 43 |

| 28.5 | 4622 | 5282 | 2000 | 622 | 2280 | 144.3 | 26730 | 47 | 80 |

| 31.5 | 5307 | 6217 | 2000 | 1307 | 2280 | 152.3 | 32820 | 47 | 80 |

| 50 | 13.5 | 9 | A5

2M | 0-3.2 | 3569 | 4153 | 1400 | 769 | 980 | 1880 | 1560 | 1260 | 2105 | 150.0 | 4000.0 | 11450 | 47 | 43 |

| 16.5 | 3569 | 4153 | 1400 | 769 | 2105 | 153.9 | 14500 | 47 | 43 |

| 19.5 | 3898 | 4522 | 1400 | 1098 | 2105 | 151.6 | 17770 | 47 | 43 |

| 22.5 | 3878 | 4558 | 1300 | 1278 | 2105 | 167.9 | 22490 | 47 | 43 |

| 25.5 | 4354 | 5176 | 1600 | 1154 | 2105 | 183.6 | 25220 | 47 | 43 |

| 28.5 | 4578 | 5610 | 1600 | 1478 | 2205 | 189.3 | 29920 | 47 | 80 |

| 31.5 | 4887 | 5797 | 1600 | 1687 | 2205 | 198.0 | 34980 | 47 | 80 |

Welcome to buy the newest and competitive price DAWSON DIN/FEM Standard Electric Double Girder Crane For Loading from our factory. We're one of the leading China manufacturers and suppliers, offering you the wholesale service and the OEM service at a discount. With CE certification, our products made in China in stock are high in quality and low in price. Please be free to get the free sample from us.

For further information, please contact us. Email:info@dawson-group.com

Note: 1、This crane travelling standard speed for 5-25 m/min (frequency conversion control), the trolley standard speed is 5-20 m/min (frequency conversion control).

2、Control mode: button switch, remote control, button switch + remote control, cabin, optional.

3、Technical parameter table is for reference only ,specific and special requirements please contact us.

English

English